Wire Harness Applications and Critical Safety Guidelines

Case 2025-10-10

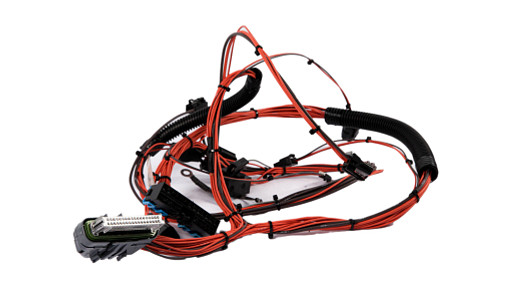

A wire harness, also referred to as a cable assembly, is an organized bundle of wires, cables, and connectors that transmits electrical power and signals within a system. By consolidating wiring into a single unit, it simplifies installation, reduces electromagnetic interference (EMI), and protects conductors from environmental damage. Its role as the “nervous system” of electrical equipment makes it essential across diverse industries, while strict adherence to safety protocols ensures reliable and hazard-free operation.

Key Application Fields of Wire Harnesses

Wire harnesses are integral to both conventional and cutting-edge technologies due to their efficient signal and power transmission capabilities. In the automotive industry, particularly for new energy vehicles (NEVs), high-voltage wire harnesses serve as the backbone of electric propulsion systems. Passenger EVs typically use harnesses rated for 600VAC/900VDC, while commercial electric buses require higher ratings of 1000VAC/1500VDC to handle currents up to 400A for high-power motors. These harnesses feature tin-plated copper braided shielding (≥85% density) to minimize EMI and insulation layers that withstand浸水50Hz AC voltage tests without breakdown. With global NEV production escalating—China alone manufactured 12.888 million units in 2024—the demand for specialized automotive wire harnesses continues to grow exponentially.

In telecommunications, 5G base stations rely on compact, high-frequency wire harnesses to connect antennas, transceivers, and power modules, ensuring seamless data transmission with minimal signal loss. The industrial automation sector uses ruggedized harnesses in robotic arms, assembly lines, and CNC machines, where they must endure constant vibration and temperature fluctuations (-40℃ to 125℃). Additionally, wire harnesses are crucial in aerospace (avionics systems), medical devices (diagnostic equipment), renewable energy (solar inverters and wind turbine controls), and consumer electronics (smartphones and home appliances).

Application Industries for Wire Harnesses

The automotive aftermarket depends heavily on wire harnesses for vehicle repairs and customization, with specialized kits for different NEV high-voltage platforms (e.g., 800V systems). The telecommunications infrastructure industry procures millions of harnesses annually for 5G network expansion, requiring compliance with strict signal integrity standards. Aerospace and defense manufacturers use lightweight, flame-retardant harnesses that meet MIL-STD specifications for extreme environments. The medical equipment industry demands sterile, chemical-resistant harnesses for devices like MRI machines and patient monitors, while the industrial machinery sector utilizes abrasion-resistant variants for heavy-duty applications.

Essential Safety Precautions for Wire Harnesses

1. Compliance with Voltage and Current Ratings: Select wire harnesses that match the system’s voltage and current requirements. For NEV high-voltage circuits, ensure harnesses meet the specified 600VAC/900VDC (passenger) or 1000VAC/1500VDC (commercial) ratings to prevent insulation breakdown and arcing. Never use low-rated harnesses in high-power applications, as this can lead to overheating and fire hazards.

2. EMI Shielding Verification: For sensitive electronics like 5G equipment and automotive ECUs, confirm that harnesses have adequate shielding (e.g., ≥85% density braided copper) to reduce electromagnetic interference. Test shielding effectiveness using impedance measurement tools to ensure compliance with industry standards.

3. Proper Installation and Routing: Follow manufacturer guidelines for routing harnesses away from heat sources (e.g., engine exhausts, resistors) and moving parts. Use cable ties that meet IEC 62275:2022 standards, which specify requirements for tensile strength, UV resistance, and temperature tolerance. Avoid over-bending harnesses (maintain minimum bend radius) to prevent conductor damage and signal degradation.

4. Environmental Protection: Install appropriate protective sleeves or conduits for harnesses in harsh environments. For outdoor applications (e.g., solar farms, construction equipment), use waterproof and UV-resistant materials with an IP rating of at least IP65. In industrial settings, choose abrasion-resistant sheathing to withstand mechanical wear.

5. Regular Inspection and Maintenance: Conduct periodic checks (monthly for industrial use, bi-annually for automotive) to: Inspect insulation for cracks, fraying, or chemical damage; check connectors for corrosion or loose pins; verify shielding integrity; and test continuity with a multimeter. Replace damaged harnesses immediately, as compromised wiring can cause system failures or safety risks.

6. Qualified Personnel for Installation: Ensure high-voltage wire harness installation (e.g., in NEVs) is performed by certified technicians trained in electrical safety. Disconnect power sources before servicing harnesses and use insulated tools to prevent electrocution. For automotive applications, follow OEM-specific procedures to avoid voiding warranties.

Conclusion

Wire harnesses are the lifeline of modern electrical systems, enabling safe and efficient power and signal transmission across industries. From automotive EVs to 5G networks, their performance directly impacts equipment reliability and safety. By adhering to voltage ratings, verifying shielding, following proper installation practices, and conducting regular maintenance, users can maximize the lifespan of wire harnesses and mitigate potential hazards. As technology advances, the demand for specialized, high-performance wire harnesses will continue to rise, making adherence to safety guidelines more critical than ever.