ABS Fuse Protection Enhancing Anti Lock Braking System Electronic Safety and Durability

News 2025-11-17

Anti-lock braking systems (ABS) depend on sensitive electronic modules, wheel speed sensors, valves, and pumps that must operate flawlessly under harsh automotive conditions. Voltage spikes, short circuits, wiring faults, or moisture intrusion can quickly damage these components if no dedicated protection is in place. An ABS fuse, purpose‑designed for this safety subsystem, isolates faults before they propagate, reducing the risk of module failure and preserving braking stability. By integrating the correct fuse type and rating into the ABS power circuit, vehicle manufacturers enhance both road safety and system longevity.

Application Scenarios in Modern Vehicles

ABS fuses are widely used in passenger cars, commercial trucks, buses, and off‑highway equipment where repeated hard braking and vibration are common. In compact cars and SUVs, the ABS fuse typically protects the electronic control unit (ECU) and pump motor from wiring harness shorts caused by abrasion or minor collisions. Heavy‑duty trucks rely on higher current fuses to secure trailer ABS circuits and multiple wheel speed sensors operating over extended distances. Electric and hybrid vehicles employ ABS fuses in combination with other protection elements to manage complex 12 V and high‑voltage architectures, ensuring the ABS module remains isolated from faults in auxiliary loads such as lighting, steering assist, or infotainment systems.

Performance Characteristics and Safety Benefits

A dedicated ABS fuse is selected based on precise current rating, time‑current characteristics, and interrupting capacity. Fast‑acting designs respond quickly to severe short circuits, while time‑delay profiles tolerate brief inrush currents from pump motors without nuisance opening. High interrupt ratings enable the fuse to safely clear faults on circuits with elevated available fault current, preventing conductor overheating and potential fire hazards. Stable performance over a wide temperature range supports consistent protection in cold starts or high‑temperature engine bays. By opening safely during abnormal conditions, the fuse prevents catastrophic damage to the ABS ECU and maintains controlled braking behavior, often allowing a fallback to conventional hydraulic braking rather than complete loss of function.

Selection, Integration, and Compliance

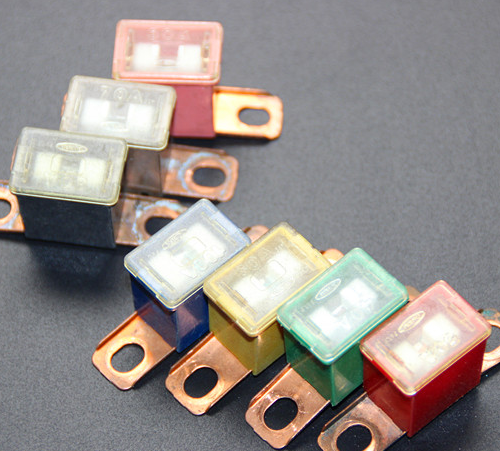

Engineers choosing an ABS fuse evaluate vehicle voltage, steady‑state load, peak inrush current, and wiring gauge to determine suitable fuse class and rating. Blade fuses, cartridge fuses, and mini blade types are common in automotive junction boxes, where compact dimensions and low contact resistance are important. The fuse location is typically near the battery or main distribution center so that the protected ABS wiring remains downstream of the device. Design teams confirm compliance with automotive standards such as ISO 26262 functional safety requirements and relevant ECE or SAE regulations. Careful coordination of the fuse rating with harness design, connector quality, and diagnostic strategies in the ECU supports accurate fault detection, simplified service procedures, and reduced warranty costs.

Maintenance, Diagnostics, and Service Considerations

From a service perspective, a clearly labeled ABS fuse simplifies troubleshooting of braking warnings or indicator lamps. Technicians can quickly verify continuity using a multimeter or visual inspection of transparent fuse bodies. When replacement is required, using the specified amperage and fuse type is crucial; oversizing may expose ABS components to dangerous fault currents, while undersizing can cause frequent unwanted openings. Integration with onboard diagnostics allows the ECU to log events linked to fuse operation, supporting predictive maintenance strategies across vehicle fleets. High‑quality ABS fuses featuring corrosion‑resistant terminals and robust housing materials maintain low contact resistance over years of thermal cycling and vibration, supporting consistent ABS performance and driver confidence.

1、What happens when an ABS fuse blows?

The ABS warning light usually illuminates, and the system may revert to standard hydraulic braking without anti‑lock modulation, while basic braking remains available so the vehicle can be driven to a service center.

2、How should engineers choose the correct ABS fuse rating?

They assess nominal ABS current, startup inrush of the pump motor, harness capacity, and applicable safety standards, then select a fuse whose time‑current curve prevents nuisance openings yet clears short circuits quickly.

3、Can a generic fuse replace a dedicated ABS fuse in the circuit?

Substituting an unapproved fuse type is not recommended, as mismatched characteristics can compromise protection performance, reduce diagnostic accuracy, and potentially violate automotive safety regulations.