Auxiliary Fuse Solutions That Protect Add‑On Electronics In Modern Vehicles

News 2025-11-17

Auxiliary fuses play a key role in safeguarding add‑on electronics such as LED light bars, navigation units, USB chargers, and communication radios. As vehicles integrate more aftermarket and auxiliary loads, dedicated fuse protection ensures that extra circuits do not overload OEM wiring or compromise safety. By isolating each accessory on its own protected branch, the auxiliary fuse maintains stable power delivery and minimizes the risk of thermal damage, nuisance resets, and unexpected shutdowns.

Typical Application Scenarios

Auxiliary fuses are widely used wherever drivers or operators install new electrical accessories beyond the factory configuration. Common examples include off‑road and work vehicles adding high‑power lighting, refrigerated cargo compartments, dash cameras, GPS trackers, and multi‑port USB charging hubs. In commercial fleets, auxiliary fuse blocks support telematics devices, cameras, and driver‑monitoring systems without touching the main OEM harness. Marine, RV, and specialty vehicles also rely on auxiliary fuse panels to organize and protect DC loads such as pumps, inverters, and entertainment systems.

Key Performance Benefits

An auxiliary fuse delivers several performance advantages over running accessories directly from an unswitched feed. First, proper current rating and fast‑acting characteristics prevent wiring from carrying more current than it was designed to handle, effectively lowering fire risk. Second, individual fusing per circuit improves fault isolation, allowing one failed accessory to trip its own fuse instead of pulling down the entire system. Third, correctly placed auxiliary fuses help stabilize voltage at the load, reducing flicker in LED lighting and noise in audio or RF equipment. Many modern fuse options feature low contact resistance and compact footprints, supporting stable performance in limited space.

Selection, Integration, and Safety Considerations

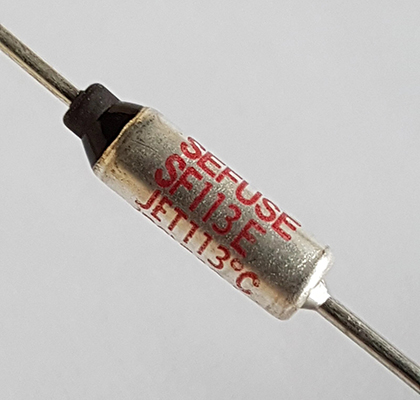

Selecting the appropriate auxiliary fuse involves matching the continuous current of the accessory, its inrush profile, and the cross‑section of the associated wiring harness. Blade‑type automotive fuses, mini and low‑profile variants, or even resettable polymer devices are commonly used in auxiliary panels. Engineers should mount the fuse as close as possible to the power source to limit the length of unprotected cable. Coordination with upstream protection and adherence to standards such as ISO and SAE specifications ensures that fuse operation aligns with the vehicle’s overall electrical protection strategy. Correct sizing, clear labeling, and weather‑resistant housings are crucial in harsh environments.

Impact On System Efficiency and Serviceability

A well‑designed auxiliary fuse layout not only protects add‑on electronics but also simplifies future maintenance and upgrades. Technicians can quickly identify circuits, verify ratings, and replace fuses without disturbing OEM components. Organized auxiliary fuse boxes reduce troubleshooting time when diagnosing faults in lights, chargers, or communication gear. This approach supports scalable wiring architectures, enabling fleets and individual users to expand capability over time while maintaining energy efficiency, consistent voltage distribution, and higher overall system uptime.

1、Why do LED light bars need dedicated auxiliary fuses?

LED light bars often draw significant current and may be installed far from the battery. A dedicated auxiliary fuse sized to the wiring prevents overheating and isolates faults to the lighting circuit.

2、Can one auxiliary fuse protect several chargers at once?

Multiple chargers can share a single fused line if the total current remains below the fuse rating and wiring capacity, but individual fusing per outlet improves protection and diagnostic clarity.

3、Where should an auxiliary fuse block be installed in a vehicle?

The fuse block should be mounted close to the main power source or distribution point, in a dry, accessible location that allows short, well‑routed cables to each accessory load.