Battery Box Universal Fit Solution for Domestic and Imported Passenger Vehicles

News 2025-11-17

A battery box with universal fit has become a key accessory for modern passenger vehicles, especially as electrical loads increase in both domestic and imported car models. By standardizing mounting dimensions, cable routing options, and ventilation paths, a universal battery enclosure streamlines maintenance and upgrades for workshops and fleet operators. The concept focuses on accommodating a wide range of battery group sizes, terminal layouts, and vehicle-specific mounting locations while maintaining strict safety and durability standards.

Universal Compatibility Across Vehicle Platforms

A universal-fit battery box is engineered to match the most common battery footprints used in sedans, SUVs, light trucks, and compact city cars from major global manufacturers. Adjustable brackets, multi-slot bases, and modular spacers allow the same enclosure to secure DIN, JIS, and BCI standard batteries in both left-hand and right-hand terminal configurations. This flexibility is especially valuable for mixed fleets containing domestic vehicles and imported brands, where engine compartments and trunk layouts vary significantly. By reducing the need for multiple dedicated housings, logistics and inventory management become simpler for distributors, service centers, and aftermarket retailers.

Protection, Thermal Management, and Electrical Safety

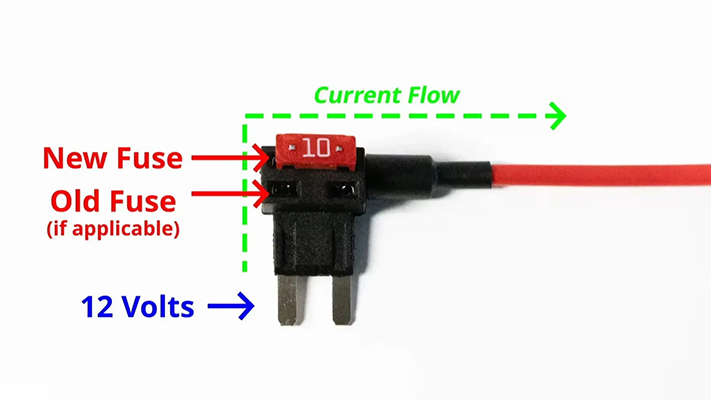

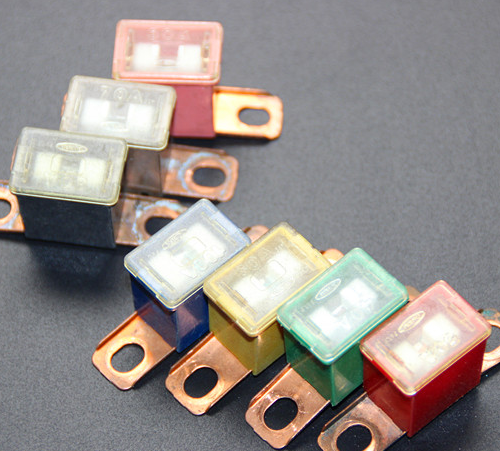

A well-designed universal battery box must do more than hold the battery in place. Robust impact-resistant polymer or coated steel construction shields cells from vibration, road debris, and accidental contact during servicing. Built-in ventilation slots and optional vent tube ports help manage heat and gases, supporting stable battery temperature and mitigating the risk of acid fumes accumulating in enclosed spaces. Secure cable entry points, integrated grommets, and clearly marked polarity zones support correct wiring practices and help prevent short circuits. These safety-focused details are particularly important for vehicles that experience frequent stop‑start cycles or heavy use of auxiliary loads, such as taxis and commercial delivery cars.

Installation Scenarios and Practical Applications

The universal battery box is suitable for front-engine bays, trunk-mounted systems, and under-seat compartments where space is limited and access is constrained. Mechanics benefit from standardized mounting holes and quick-release covers that support faster replacement intervals and consistent torque on hold-down hardware. For vehicles upgraded with high-output audio systems, off-road lighting, or auxiliary inverters, the enclosure supports dual-battery configurations when paired with appropriate brackets. RV conversions, ride‑share fleets, and corporate pool cars all benefit from the ability to deploy the same enclosure model across different platforms, simplifying service training and reducing downtime.

Performance Benefits and Long-Term Cost Savings

Universal-fit battery boxes contribute to longer battery life by improving mechanical stability and thermal conditions. Reduced vibration lowers the risk of internal plate damage, while controlled airflow supports more stable charge and discharge characteristics in both flooded and AGM chemistries. Corrosion-resistant materials and secure lids help keep dust, moisture, and engine-bay contaminants away from terminals and connectors, supporting consistent starting performance in hot summers and cold winters. From an economic perspective, stocking a single enclosure that fits most domestic and imported cars reduces purchasing complexity, supports bulk procurement, and minimizes the chance of installation errors caused by unsuitable generic trays.

Common Questions About Universal Fit Battery Boxes

1. Does a universal battery box affect vehicle warranty?

In most cases, a properly installed universal battery box that meets automotive safety standards does not affect manufacturer warranties. Installers should follow vehicle OEM guidelines and avoid modifications that alter structural components.

2. Can one battery box model handle both standard and AGM batteries?

Yes, as long as the enclosure provides correct venting, secure clamping, and adequate space for the specific case size. Many designs include adjustable inserts to match different chemistries and dimensions.

3. Is special tooling required for installation?

No specialized tools are typically required beyond common workshop hand tools. Clear mounting diagrams and multi-position brackets enable technicians to fit the battery box in a range of engine bays and trunk areas efficiently.