Blade Type Fuse Design That Simplifies Fast Replacement And Clear Identification In Vehicles And Equipment

News 2025-11-17

Blade-type fuse popular design simplifies replacement and identification.

Structure And Visual Identification Benefits

Blade-type fuses are built around a flat plastic body combined with two parallel metal blades, a format that has become a de facto standard in automotive and low-voltage DC systems. The transparent or translucent housing exposes the fusible element, allowing technicians to verify status at a glance. Color-coded bodies and large, embossed ampere ratings help differentiate current values quickly in dense fuse boxes. This visual clarity reduces human error when servicing, particularly in crowded harnesses behind dashboards or inside industrial control cabinets. The standardized footprint also supports compact layouts while keeping replacement straightforward for maintenance staff.

Performance Characteristics And Protection Capabilities

Blade fuses are optimized for low-voltage DC circuits, typically 12 V, 24 V, and 48 V systems, and are available in multiple speed classes to match load characteristics. Time-delay variants tolerate short inrush currents from motors, pumps, and lighting ballasts, while fast-acting types respond rapidly to wiring faults and short circuits. Carefully defined I²t values and interrupt ratings allow engineers to coordinate fuses with upstream protection and conductor sizes, preventing nuisance trips while safeguarding insulation. Their stable contact resistance and low power dissipation support reliable operation in high-density panels where thermal management is a concern.

Application Scenarios In Automotive And Industrial Systems

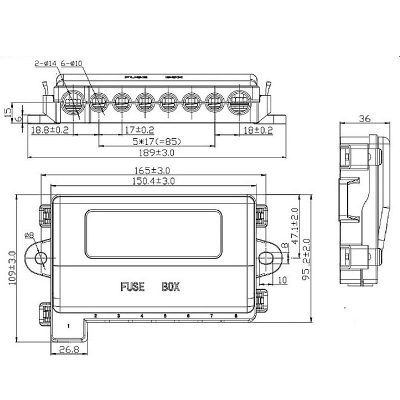

The most visible use case is the automotive fuse box, where blade-type fuses protect lighting, infotainment, ADAS controllers, HVAC blowers, and accessory power outlets. Commercial vehicles extend this role to liftgates, refrigeration units, and telematics modules operating in harsh vibration and temperature conditions. Beyond transportation, these fuses appear in AGVs, material-handling equipment, battery-powered tools, solar charge controllers, and marine distribution panels. Their standardized blade interface integrates easily into printed circuit fuse holders, modular distribution blocks, and sealed IP-rated housings, which simplifies system design and retrofits in field-service environments.

Serviceability, Safety, And Design Optimization

Service technicians value blade fuses because they can be removed using simple pullers without disturbing surrounding wiring, reducing downtime during troubleshooting. Clear ratings and mechanical keying between mini, standard, and maxi sizes discourage incorrect insertion, enhancing safety in fleet maintenance and rental equipment. From a design perspective, engineers can use widely available derating curves and temperature profiles to select suitable fuse families during early schematic stages. This shortens validation cycles and supports scalable product platforms where power distribution architectures are shared across multiple models or voltage classes.

Three Common Questions About Blade-Type Fuses

1. How should I select the current rating?

Choose a rating slightly above the normal operating current while remaining within conductor and connector limits, and verify performance using the manufacturer’s time-current curves.

2. Are blade fuses suitable for marine and outdoor use?

Yes, when paired with sealed or splash-proof fuse holders that provide corrosion resistance and maintain low contact resistance under humidity and salt exposure.

3. Can blade-type fuses protect sensitive electronics?

They can, especially fast-acting versions, but pairing them with transient voltage suppressors or resettable protectors often yields better protection for delicate semiconductor circuits.