Compact Automotive Battery Box Design for Confined Engine Bay Applications

News 2025-11-17

Compact automotive battery boxes are increasingly important as modern engine bays become tighter and more crowded with electronic subsystems. Vehicle manufacturers need enclosures that protect high-capacity batteries while fitting within restricted spaces, supporting high electrical loads, and simplifying maintenance. A well-engineered compact battery box must balance thermal management, mechanical strength, vibration resistance, and safety requirements, all while integrating cleanly with existing harnesses and power distribution modules.

Space-Constrained Installation Scenarios

Compact battery boxes are designed for applications where every millimeter matters: downsized engine compartments, hybrid and plug-in hybrid layouts, aftermarket audio or lighting upgrades, and commercial vehicles retrofitted with telematics or auxiliary power units. In these environments, the battery enclosure often needs to fit between structural members, around air ducts, or near high-temperature powertrain components. A compact footprint with optimized height and width helps technicians position the box in corner spaces while maintaining access to terminals, fuses, and service points. Configurable mounting brackets and multiple cable entry options allow the same platform to be used across different vehicle models and trim levels.

Performance and Protection Features

Although the enclosure is compact, it must deliver robust electrical and mechanical performance. High-impact, heat-resistant materials protect the battery from debris, engine vibration, and fluid exposure common in harsh under-hood environments. Integrated venting channels help dissipate heat and manage gas release from lead-acid or AGM batteries, reducing the risk of pressure buildup. Sealed lids and gasketed joints prevent moisture ingress, supporting stable performance in high-humidity regions and during cold starts. Reinforced terminal zones support high current draw for start-stop systems, high-powered ECUs, and aftermarket accessories without excessive voltage drop or thermal hotspots.

Integration with Vehicle Electrical Architecture

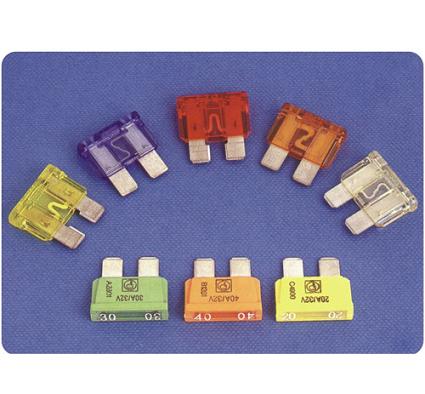

A compact battery box must cooperate with the wider electrical architecture rather than acting as an isolated component. Many designs include provisions for integrated fuse blocks, current sensors, and battery management system connections, simplifying routing and diagnostics. Top-mounted service windows or removable covers give technicians fast access to diagnostic points, enabling efficient troubleshooting and reducing workshop downtime. Clear polarity markings, cable clamps, and strain-relief features minimize installation errors and protect wiring looms from chafing, which is especially important in engine bays with limited clearance and frequent thermal cycling.

Durability, Compliance, and Lifecycle Value

Durability is a key selection factor for OEMs and fleet operators. Compact battery boxes for tight engine bays typically undergo vibration, shock, salt spray, and thermal cycling tests to align with automotive standards for safety and endurance. UV-stable polymers and corrosion-resistant metal hardware maintain structural integrity over long service lives, even in off-road or high-mileage fleet conditions. By extending battery lifespan and reducing unexpected failures, a well-designed enclosure lowers total cost of ownership and supports sustainability targets. Compatibility with common battery form factors and regional standards simplifies global platform development and reduces inventory complexity across different vehicle lines.

FAQs: Compact Battery Boxes for Tight Engine Bays

1. Where are compact automotive battery boxes most commonly used?

They are widely used in passenger cars with crowded engine bays, light commercial vehicles, hybrid platforms, and aftermarket upgrades that require secure battery mounting in confined spaces.

2. How does the enclosure improve battery performance?

By providing thermal control, vibration damping, and moisture protection, the enclosure helps maintain stable operating conditions, which can extend battery life and support consistent cold-start performance.

3. What should engineers consider when selecting a battery box for a new platform?

Key criteria include available installation space, required current rating, environmental exposure, compatibility with existing wiring and BMS hardware, and compliance with relevant automotive safety and durability standards.