Components of Heavy-Duty Wire Harnesses in Agricultural Machinery Electrical Systems

News 2025-10-31

In the agricultural industry, where machinery operates under extreme conditions, heavy-duty wire harness components are fundamental to maintaining efficient and reliable electrical systems. These parts ensure that tractors and implements perform optimally, supporting everything from basic lighting to advanced automated controls. By organizing and protecting wiring, they prevent failures that could disrupt farming operations, ultimately contributing to higher productivity and cost savings in the field.

Application Scenarios in Farming

Heavy-duty wire harness components are deployed in various agricultural applications, such as connecting sensors for precision planting in tractors or managing electrical demands in implements like harvesters and sprayers. In dusty, wet, or high-vibration environments typical of fieldwork, these components maintain signal integrity and power distribution. For example, in autonomous tractors, they facilitate real-time data transfer for GPS-guided operations, enabling accurate crop management and reducing human error.

Performance Benefits for Durability

These wire harness elements excel in harsh conditions due to their robust construction, offering resistance to abrasion, moisture, and temperature extremes. Constructed from high-grade materials like reinforced polymers and corrosion-resistant metals, they minimize wear and extend equipment lifespan. This durability translates to fewer breakdowns during peak seasons, enhancing operational efficiency and allowing farmers to focus on productivity rather than repairs.

Key Features and Material Choices

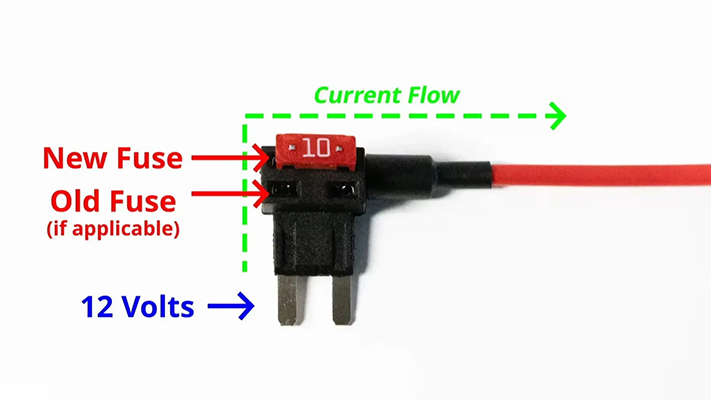

Central to these systems are components such as sealed connectors, flexible cabling, and protective sheathing, each designed for specific agricultural demands. Materials are selected for their ability to handle high electrical loads while withstanding environmental stressors, ensuring compatibility with modern tractor electronics. Proper selection based on factors like voltage tolerance and mechanical strength is crucial for integrating these parts seamlessly into existing machinery.

1. What are the primary functions of wire harness components?

They organize wiring, provide secure connections, and protect against environmental damage to ensure reliable electrical performance.

2. How do these components handle extreme weather conditions?

Designed with weatherproof seals and robust materials, they resist water ingress, dust, and temperature fluctuations common in outdoor farming.

3. Why are custom wire harnesses important for agricultural use?

Customization allows for tailored fits to specific machinery, improving efficiency and reducing the risk of electrical failures in diverse applications.