Comprehensive Strategies for Enhancing Durability in Automotive Battery Housing Through Rigorous Quality Testing

News 2025-10-20

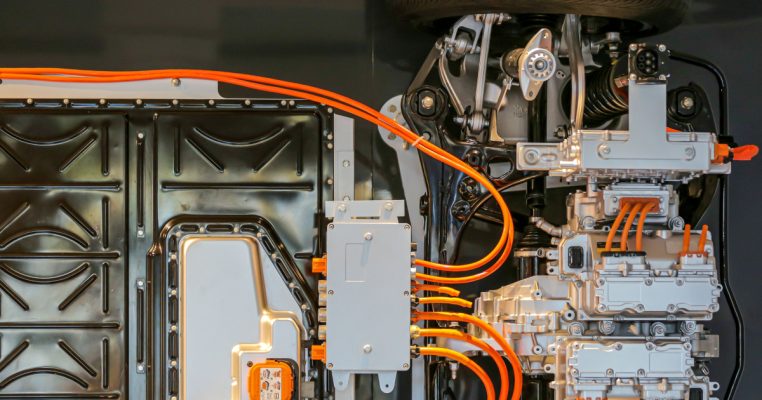

The automotive sector demands robust car battery boxes to support everything from daily commutes to high-performance electric vehicles. These components must withstand extreme conditions like vibrations, temperature fluctuations, and chemical exposures to ensure safety and longevity. Quality testing methods play a pivotal role in preempting failures, reducing warranty claims, and meeting stringent industry standards. By focusing on these tests, manufacturers can deliver products that excel in real-world applications, ultimately boosting vehicle reliability and user satisfaction.

Core Testing Methodologies

Quality testing for car battery boxes encompasses a range of methodologies designed to simulate operational stresses. Mechanical tests, such as vibration and shock assessments, mimic road conditions to check for structural integrity. Environmental simulations, including thermal cycling and humidity exposure, evaluate material resilience against weather extremes. Electrical integrity tests ensure that the box maintains insulation and prevents short circuits, all while adhering to standards like ISO 16750. These methods collectively identify weaknesses, allowing for design improvements that enhance overall durability and performance in automotive settings.

Practical Application in Vehicle Systems

In electric and hybrid vehicles, battery boxes are critical for housing high-voltage systems, where testing methods ensure they handle energy demands without degrading. For instance, in urban driving scenarios, boxes must resist frequent stop-start cycles, while long-haul applications require endurance against prolonged vibrations. Performance advantages include extended battery life and reduced risk of thermal runaway, directly impacting energy efficiency and safety. By applying these tests, manufacturers tailor boxes to specific vehicle types, optimizing weight, space, and cost-effectiveness for better market competitiveness.

Frequently Asked Questions

1. What are the main benefits of quality testing for battery boxes?

Answer: It ensures long-term reliability, reduces failure rates, and complies with safety regulations, enhancing vehicle performance.

2. How do testing methods adapt to different car models?

Answer: Tests are customized based on vehicle specifications, such as size and power requirements, to address unique durability challenges.

3. Why is durability testing essential for electric vehicles?

Answer: It prevents issues like corrosion and fatigue, supporting the high cycle life needed for EVs and improving overall energy management.