Corrosion-Resistant Inline Fuse Holder in Saltwater Boat Applications

News 2026-01-12

Saltwater environments relentlessly attack electrical components on marine vessels, as salt crystals and humidity accelerate corrosion and threaten circuit reliability. Specialized inline fuse holders engineered for these conditions provide secure enclosures that protect fuses and wiring against moisture ingress. By using durable housings and precision seals, marine systems maintain consistent power delivery to navigation, lighting, and communications equipment across coastal and offshore operations.

Corrosion Protection and Material Selection

Marine-grade inline fuse holders rely on high-performance plastics such as UV-stabilized polycarbonate or reinforced nylon to withstand saltwater exposure. Critical contact points employ brass or stainless steel terminals treated with nickel or tin plating to inhibit oxidation. Integrated O-ring seals and gasket interfaces ensure IP66 or higher protection against jetting water and particulate intrusion. These material choices extend service life in sunlit decks or submerged compartments, reducing the need for frequent replacement.

Installation in Vessel Electrical Systems

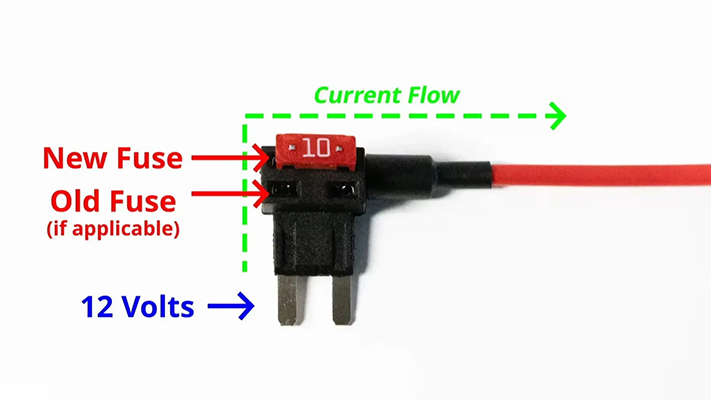

For installation aboard recreational yachts or commercial boats, inline fuse holders offer versatile mounting options including panel clamps, bulkhead fittings, and DIN rail clips. They accommodate standard automotive-style fuses and blade-type fuses, blending seamlessly into wiring harnesses feeding bilge pumps, radar modules, and deck lighting circuits. Snap-in covers or twist-lock caps provide tool-free access, streamlining routine inspections and upgrades while minimizing deck clutter.

Performance Under Saltwater Exposure

Products undergo rigorous salt spray testing and thermal cycling to verify resistance to humidity, temperature swings, and UV radiation. Shock and vibration assessments simulate engine vibrations and rough sea conditions, confirming terminal stability under dynamic loads. Pressure-tested housings prevent microleaks during heavy spray or deck washdowns, while flame-retardant compounds meet marine safety standards. This performance profile ensures uninterrupted protection in harsh marine environments.

Maintenance and Replacement Efficiency

Every inline fuse holder is designed for straightforward access, often featuring transparent covers or hinged lids that reveal fuse status at a glance. Quick-release mechanisms allow swap-outs of blown fuses without specialized tools, cutting service time in tight engine compartments or amid active deck operations. Compact inline designs conserve panel space and integrate with wire looms, supporting modular repairs and scalable circuit layouts on vessels of varying sizes.

1、What features enable this fuse holder to resist corrosion on marine boats?

The combination of UV-stable housing materials, nickel-plated terminals, and IP66-rated sealing ensures that moisture, salt spray, and UV radiation cannot breach the enclosure, preserving circuit integrity.

2、Is installation possible in cramped engine compartments?

Yes. The compact inline footprint, multiple mounting options, and tool-free access mechanisms allow secure installation even in tight or hard-to-reach spaces.

3、Can different fuse types be used interchangeably?

Inline holders support a range of blade and cylindrical automotive fuses, enabling compatibility with standard marine circuits and simplifying inventory management.