Critical Aspects of Wire Harness Weight Reduction and Space Optimization in Compact Automotive Electrical Systems

News 2025-10-24

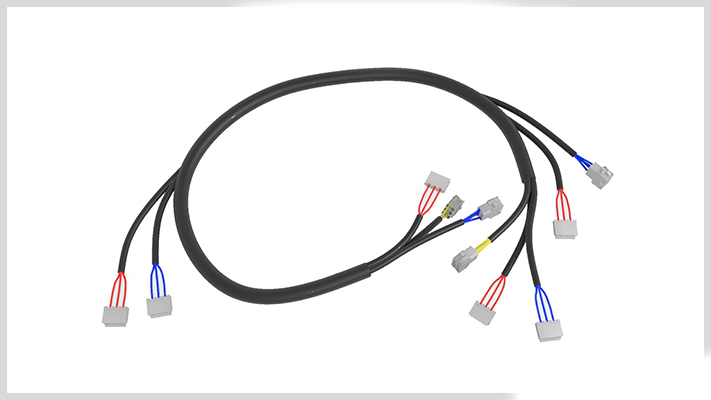

In the design of compact cars, electrical systems are vital for performance and efficiency. Wire harnesses serve as the backbone for organizing and protecting electrical wires, ensuring reliable power distribution and signal transmission. However, in vehicles with limited space, such as compact cars, the weight and spatial demands of these harnesses can affect fuel economy, handling, and overall design feasibility. Addressing these considerations is essential for engineers aiming to create lighter, more efficient automotive electrical layouts that meet stringent industry standards and consumer expectations.

Weight Reduction Strategies

Wire harness weight directly influences vehicle efficiency and emissions. By selecting advanced materials like aluminum alloys or composite polymers, manufacturers can achieve significant reductions without sacrificing durability or electrical performance. Optimizing wire sizing based on specific current loads minimizes excess material, while innovative bundling techniques reduce the need for additional support structures. These approaches not only lower the center of gravity for better stability but also contribute to cost savings in production and improved fuel efficiency in real-world driving scenarios.

Space Optimization Techniques

Efficient use of space in compact car designs enhances functionality and aesthetics. Techniques such as 3D routing and modular harness configurations allow components to fit into confined areas, reducing interference with other systems. Integrating sensors and connectors directly into the harness streamlines assembly and maintenance, freeing up valuable space for features like advanced infotainment or safety systems. Through computer-aided design tools, engineers can simulate and refine layouts to maximize space utilization, leading to sleeker vehicle profiles and better overall performance in urban environments.

1. What factors affect wire harness weight in compact cars?

Answer: Material choice, wire gauge, and layout complexity play key roles in determining weight, with lighter materials and efficient designs reducing overall mass.

2. How does space optimization impact electrical system reliability?

Answer: Proper space management prevents overheating and mechanical stress, ensuring long-term reliability and reducing failure rates in constrained environments.

3. Why is weight reduction important for compact car performance?

Answer: Lighter wire harnesses improve acceleration, handling, and fuel economy, making vehicles more competitive in the compact car market.