Dashboard Fuse Solutions That Protect Instrument Cluster Electronics And Gauge Stability

News 2025-11-17

Dashboard fuse protects instrument cluster and gauge connections

Role of the dashboard fuse in modern vehicles

The dashboard fuse is a dedicated protection element placed in the power path of the instrument cluster, pointer gauges, telltale indicators, and display controllers. It isolates the cluster electronics from wiring harness faults, reverse battery events, and short circuits caused by damaged connectors or moisture ingress. By interrupting excessive current before it reaches delicate microcontrollers and LED drivers, the fuse preserves calibration data, prevents board overheating, and avoids costly replacement of the entire cluster module. As vehicles integrate more digital displays and connectivity features, the dashboard fuse becomes a key component helping designers maintain system safety and long‑term reliability.

Application scenarios in instrument clusters and gauge networks

Dashboard fuses are used in analog and fully digital clusters, as well as hybrid layouts that mix mechanical gauges and TFT or LCD panels. Typical locations include the main 12 V supply line to the cluster, backlighting circuits, stepper‑motor gauge drivers, and CAN or LIN interface power pins. In commercial trucks and off‑highway equipment, stronger vibration and harsh temperature swings heighten the risk of wiring abrasion and shorts, making fuse selection even more critical. Electric and hybrid vehicles employ instrument clusters that monitor battery state of charge, motor temperature, and high‑voltage alerts; a properly rated dashboard fuse ensures these safety‑relevant indications continue to operate by limiting cascading failures when a local fault occurs in the auxiliary low‑voltage domain.

Performance advantages and key selection parameters

Compared with generic fuses placed elsewhere in the vehicle fuse box, dashboard fuses tailored to cluster applications offer precise current ratings, fast but controlled blow characteristics, and low internal resistance to minimize voltage drop. Designers typically analyze normal operating current of the cluster, inrush current to display backlights and microcontroller power rails, and worst‑case fault scenarios. Important parameters include rated voltage, interrupting capacity, time‑current curve, and ambient temperature derating. High‑quality fuses maintain stable characteristics over thousands of thermal cycles and under continuous vibration, preventing nuisance blows while still protecting against transient overloads. Correct specification improves driver experience by reducing flicker or random reboots of the cluster during engine cranking or cold starts.

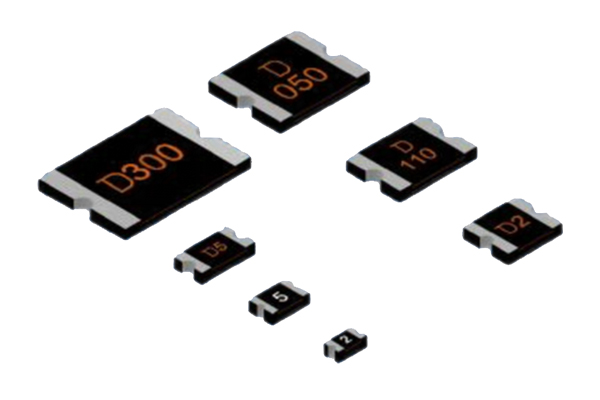

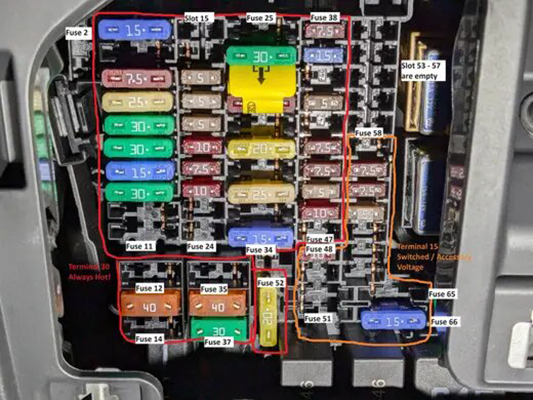

Integration considerations and maintenance benefits

The dashboard fuse can be implemented as a plug‑in blade fuse in the cabin fuse box, a mini‑fuse on a dedicated cluster harness, or a soldered surface‑mount fuse directly on the instrument cluster PCB. PCB‑mounted solutions offer shorter current paths and better noise performance, while external blade fuses simplify serviceability at the workshop. From a maintenance perspective, clear labeling and easy access shorten diagnostic time when gauges become unresponsive or the cluster goes dark. Instead of replacing displays, sensors, or the entire cluster, technicians often restore operation by tracing the failed circuit and swapping the blown dashboard fuse. This reduces downtime, lowers warranty costs, and supports stable long‑term operation in passenger cars, buses, construction machinery, and agricultural vehicles.

FAQs on dashboard fuses and instrument clusters

1. Why does an instrument cluster need a dedicated fuse?

The dedicated fuse prevents local wiring or component faults from damaging the whole cluster, protecting microcontrollers, gauges, and backlighting circuitry.

2. How do I know which fuse rating suits a dashboard application?

The rating should exceed normal operating current and inrush levels, yet remain low enough to open safely during short circuits or severe overloads as defined by the design analysis.

3. What symptoms indicate a blown dashboard fuse?

Common signs include a dead instrument panel, frozen gauges, loss of backlight, or intermittent cluster resets while other vehicle systems remain functional.