Dustproof Inline Fuse Holder Sealed Design Desert Construction Sites Applications

News 2026-01-12

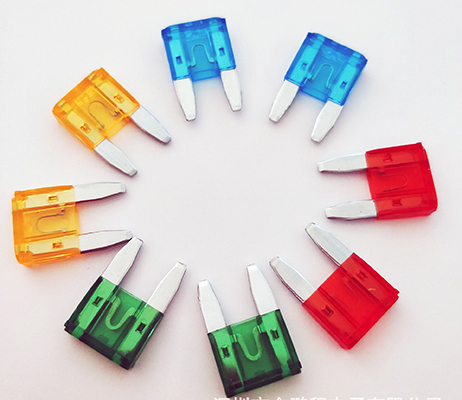

Dustproof inline fuse holder features a sealed polycarbonate housing that meets IP67 standards, ensuring protection against particulate ingress in arid and dusty environments. Operating temperature spans -40°C to +85°C, and integrated O-ring seals maintain circuit integrity against high-velocity sand or debris. Modular design accepts blade fuses up to 40A, supporting nominal voltages to 32V DC. This component adapts to solar arrays, off-grid power systems, and heavy machinery controls, delivering secure overload protection where conventional holders fail.

Application Environments

In remote desert construction sites, continuous operation demands components resistant to sandstorms, extreme heat, and equipment vibration. This fuse holder mounts on control panels of bulldozers, graders, and drilling rigs, safeguarding circuits from particulate intrusion. It also integrates into renewable energy installations, including photovoltaic farms and portable gensets. Portability and IP67 sealing reduce maintenance intervals, sustaining protection in mobile workshops, lighting towers, and remote instrumentation. Compatibility with SAE connectors streamlines integration into automotive and industrial wiring harnesses.

Performance Benefits

The sealed inline fuse holder delivers outstanding dust, moisture, and UV resistance, extending service life in exposed locations. IP67 certification permits temporary immersion and heavy particulate loads, while a stainless-steel mounting bracket resists corrosion. Low contact resistance from -40°C to +85°C ensures stable current flow and minimizes thermal hotspots. A quick-release latch accelerates fuse replacement without compromising seal integrity. Tested to ISO 16750 vibration and shock standards, the assembly maintains reliable operation under dynamic loads and harsh environmental conditions.

Installation and Maintenance

Installation requires no specialized tools: pluggable connectors, captive screws, and keyed housings align fuse clips precisely. Integrated adhesive-backed cable clamps and molded strain relief secure wiring runs against tensile stress. To service, release the latch, replace the fuse, and snap the cover back into place. Periodic inspections target gasket condition and terminal cleanliness; cleaning employs compressed air and a silicone-compatible dielectric grease on sealing surfaces. This low-maintenance design reduces lifecycle costs across mining operations, industrial plants, and remote infrastructure deployments.

1、Suitable use cases?

This fuse holder is ideal for desert-based off-grid installations, heavy machinery control panels, and mobile power distribution units in dusty or humid environments.

2、Sealing advantage?

Integrated O-ring and gasket system delivers IP67-rated protection, blocking dust and water ingress that can cause circuit failures under abrasive conditions.

3、Replacement process?

Fuse changes require only a manual latch release and direct blade extraction, ensuring rapid service and restoring circuit protection within seconds.