Easy-to-install fuse simple design enables DIY replacement without tools

News 2025-11-17

Easy-to-install Fuse Design Enables Fast DIY Replacement Without Tools

User-centered mechanical concept

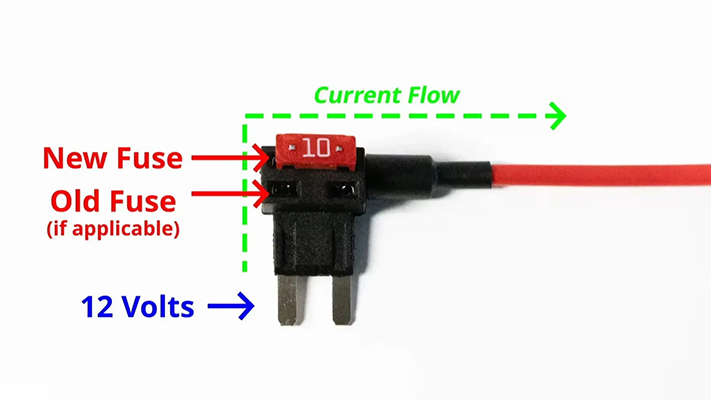

The latest easy-to-install fuse architecture focuses on mechanical simplicity so that end users can replace protection components in seconds. A finger-safe pull tab, keyed housing, and polarized contacts allow the fuse to slide into a low-profile carrier without a screwdriver or pliers. Clear markings on the cartridge and holder eliminate ambiguity about rating and orientation, supporting safe operation even in compact control panels. The design targets consumer electronics, smart home hubs, industrial control boxes, and EV charging accessories where downtime and maintenance costs must be minimized.

Performance characteristics and safety benefits

Despite its tool-free approach, this fuse maintains electrical performance expected in professional environments. Time-current curves comply with IEC and UL standards, enabling predictable coordination with upstream breakers and downstream loads. Options include fast-acting and time-delay versions, covering motor inrush, LED drivers, power adapters, and communication systems. High-interrupt ratings support fault clearing in dense PCBs. Flame-retardant housings, finger-proof terminals, and integrated visual blown indicators help engineers meet creepage and clearance requirements while simplifying field troubleshooting.

Key application scenarios in modern electronics

This simple replacement concept fits particularly well in distributed IoT nodes, network switches, and access points, where technicians must service many units quickly. In building automation, tool-free fuse holders mounted on DIN rails reduce service time in lighting cabinets and HVAC controllers. Portable medical equipment and test instruments benefit from quick fuse swaps at the point of use, cutting the need for specialized service centers. Designers of consumer audio systems, gaming consoles, and home energy monitors can integrate the holder near an external panel, enabling end users to restore functionality without exposing internal circuitry.

Design integration and maintenance advantages

From a design perspective, the fuse carrier supports both through-hole and panel-mount configurations, giving PCB engineers flexibility in mechanical layout. The compact form factor improves airflow around heat-generating components, sustaining stable performance under continuous load. Tool-free access encourages users to replace fuses instead of bypassing them, preserving long-term system safety. For OEMs and service organizations, standardized cartridges simplify inventory, while shorter service intervals improve uptime SLAs in data centers and industrial plants.

1, What types of equipment benefit most from this fuse design?

Products that require quick field service, such as smart home controllers, networking gear, EV charging accessories, and compact industrial controllers, gain the greatest benefit from the tool-free replacement concept.

2, How does the tool-free feature impact safety compliance?

The finger-safe housing, clear markings, and standardized ratings support compliance with IEC and UL standards by reducing installation errors, maintaining proper creepage, and preventing accidental contact during replacement.

3, Can this fuse system be retrofitted into existing designs?

In many cases the holder can replace traditional panel fuses or inline cartridges, provided mechanical space and voltage-current ratings match, allowing upgrades to faster maintenance without redesigning the entire power stage.