Easy-To-Integrate Thermal Fuse Simplifies Installation in Car Electrical Setups and Boosts Safety Performance

News 2025-11-27

Thermal Fuses Reshaping Modern Car Electrical Safety

Thermal protection is no longer limited to high-end vehicles. As wiring harness density, lithium battery usage, and high-power infotainment grow, compact thermal fuses are becoming standard in everyday car electrical setups. The latest easy-to-integrate thermal fuse designs allow engineers and technicians to secure harnesses, ECUs, chargers, and lighting modules against overheating without redesigning existing layouts or adding complex electronics, helping meet strict automotive safety and reliability targets.

Simplified Integration Into Existing Harnesses

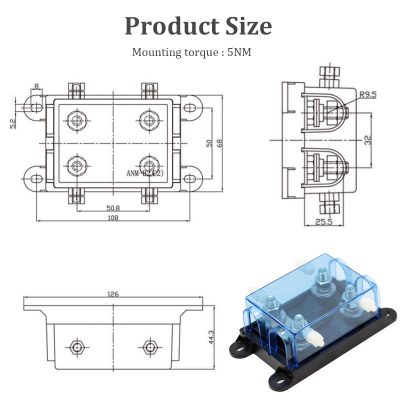

An easy-to-integrate thermal fuse is engineered around standard lead spacing, familiar crimp and solder interfaces, and compact radial or axial packages. Installers can drop the device directly into common 12 V and 48 V circuits, protecting blower motors, seat heaters, mirror defrosters, and USB power outlets. Pre-terminated options fit into junction boxes and distribution blocks, cutting assembly time and reducing wiring errors. This simple integration approach supports aftermarket upgrades as well as OEM platforms, making thermal protection practical even in tight dashboard or under-seat locations.

Performance Benefits in Demanding Automotive Conditions

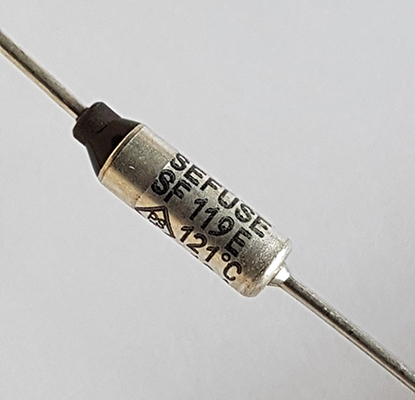

Unlike resettable devices that may allow repeated overheating, a thermal fuse offers a definitive cutoff once its calibrated temperature threshold is exceeded. High-precision organic pellets or alloy elements deliver narrow tolerance trip points, protecting wire insulation, connectors, and plastic housings from thermal damage. Automotive-grade versions are tested to endure vibration, thermal cycling, and surge conditions found in engine compartments and under-body environments. Low internal resistance minimizes power loss, while wide operating temperature ranges match the extremes experienced in global markets.

Key Application Scenarios in Vehicle Electrical Architectures

In passenger cabins, thermal fuses safeguard seat heating pads, steering wheel heaters, and interior LED strips from blocked airflow or material faults. Under the hood, they protect auxiliary pumps, cooling fans, and power distribution modules that operate in elevated ambient temperatures. In EVs and plug-in hybrids, thermal fuses are commonly placed in on-board chargers, DC‑DC converters, and battery junction boxes as a secondary layer of protection alongside sensors and electronic control. These devices help automakers comply with functional safety requirements and reduce warranty claims linked to heat-related failures.

Installation Flexibility and Design Optimization

The compact footprint of modern thermal fuses allows designers to position them close to heat sources, improving response time and decreasing the length of unprotected wiring. Options include axial leads for in-line harness integration and radial versions for PCB mounting in control modules. Clear markings on body and leads simplify quality inspection and maintenance. By using standardized device footprints and ratings, procurement teams can streamline sourcing and qualify multiple vendors without revalidating the entire circuit.

1What is the role of a thermal fuse in a car circuit?

A thermal fuse permanently opens the circuit once a preset temperature is reached, preventing overheating damage to wiring, modules, and surrounding materials.

2Where should an automotive thermal fuse be installed?

It is typically placed close to the most critical heat source, such as seat heater elements, fan motors, or power modules, ensuring fast reaction to abnormal temperature rise.

3How is a thermal fuse different from a standard fuse?

A standard fuse responds primarily to overcurrent, while a thermal fuse reacts to temperature. Many automotive designs use both, combining current protection and thermal shutdown in the same circuit.