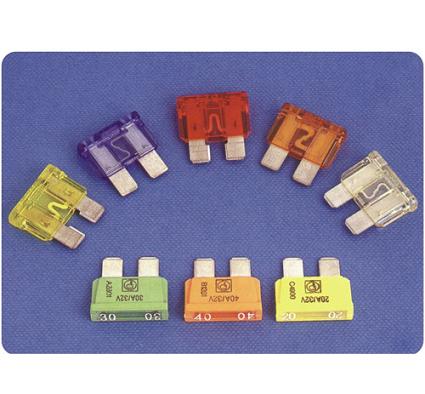

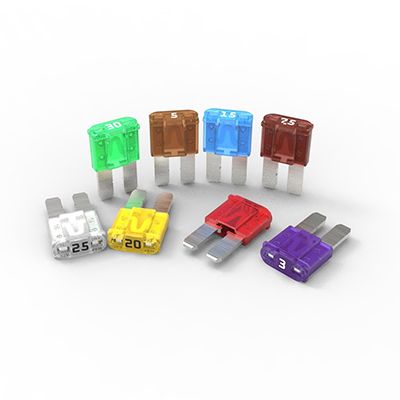

Electroplated Surface Auto Fuse Enhancing Extra Vehicle Circuit Corrosion Defense And Stability

News 2025-12-08

Electroplated surface auto fuses build a strong protective barrier around extra vehicle circuits that operate in harsh environments. In modern vehicles packed with add‑on loads such as LED light bars, infotainment modules, telematics units, and auxiliary battery systems, these fuses guard against both overcurrent events and gradual corrosion damage. By combining precise current‑limiting characteristics with engineered surface finishes, they extend wiring harness life, reduce fault frequency, and support long-term electrical reliability in passenger cars, commercial fleets, and specialty vehicles.

Electroplated Surface Technology And Corrosion Defense

Electroplated layers on the fuse terminals and element surfaces reduce oxidation, moisture‑driven corrosion, and attack from road salts or industrial pollutants. Common finishes include tin, nickel, or multi‑layer stacks tailored to the operating environment and mating connector material. These coatings lower contact resistance at the fuse holder interface, stabilizing voltage drop over time and limiting heat generation at the connection point. By slowing the formation of corrosive films, electroplated fuses maintain consistent conductivity, support accurate current ratings, and minimize nuisance openings caused by degraded contacts in under‑hood and under‑body locations.

Key Performance Advantages In Automotive Electrical Systems

Electroplated surface auto fuses provide tight tolerance on rated current and fast, predictable response to overloads, protecting sensitive ECUs, sensors, and CAN or LIN network devices. The enhanced surface finish improves solderability and mechanical fit, which is essential in high‑vibration zones around engine compartments, chassis rails, and trailer connectors. Stable contact resistance improves thermal behavior, allowing fuse blocks to remain cooler under continuous load. This supports higher density power distribution modules, simplified harness routing, and more flexible layout options in crowded vehicle architectures while maintaining high safety margins.

Application Scenarios In Extra Vehicle Circuits

Extra circuits installed after vehicle production often face higher risk than factory wiring, because they may be routed through exposed areas and experience variable installation quality. Electroplated surface auto fuses are widely used in aftermarket lighting kits, winches, air compressors, refrigeration units, camper conversions, and fleet telematics systems. In these applications, moisture ingress, dust, and road debris can quickly corrode unprotected terminals. By using electroplated fuses in sealed or semi‑sealed fuse holders, integrators maintain consistent current paths and reduce service intervals. This is particularly valuable for off‑road vehicles, emergency response fleets, and logistics trucks that operate in coastal or winter climates.

Design And Selection Considerations

When selecting electroplated surface auto fuses, engineers weigh rated current, voltage, time‑current curves, interrupt rating, and compatibility with the chosen fuse holder or PCB footprint. Matching the plating system to the contact material avoids galvanic corrosion and ensures stable mating force over the product lifetime. Designers also consider ambient temperature, expected duty cycle, and peak inrush currents from motors or capacitive loads. Adopting standardized blade or cartridge formats simplifies replacement and supports global service networks. By specifying electroplated fuses early in the design stage, OEMs and upfitters can reduce warranty claims, improve electrical fault isolation, and maintain compliance with automotive safety and EMC regulations.

1. Why choose electroplated fuses in coastal regions?

Electroplated surfaces resist salt‑induced corrosion, preserving low contact resistance and preventing intermittent power loss in marine‑adjacent or high‑humidity environments.

2. How do these fuses benefit fleet operations?

Stabilized electrical connections cut unplanned downtime, reduce maintenance calls related to auxiliary systems, and support accurate fault diagnostics across large vehicle fleets.

3. Are electroplated auto fuses suitable for retrofits?

Yes, they integrate easily into existing fuse blocks or add‑on distribution modules and significantly enhance durability of aftermarket circuits subject to moisture and vibration.