Engineered Wire Harness Assemblies for Automotive Air Conditioning Compressor Electrical Systems

News 2025-10-31

In the automotive industry, wire harness assemblies are vital components that ensure the efficient and safe operation of air conditioning compressor electrical systems. These assemblies integrate multiple wires, connectors, and components to handle power distribution and signal transmission, supporting the complex demands of modern vehicles. By providing a structured and reliable electrical pathway, they help maintain optimal performance in varying environmental conditions, contributing to the overall functionality of automotive HVAC systems.

Application Scenarios

Wire harness assemblies find critical use in diverse automotive applications, particularly in air conditioning compressors for passenger cars, trucks, and electric vehicles. They connect sensors that monitor refrigerant levels, control modules that regulate compressor speed, and actuators that manage airflow, ensuring precise operation during extreme temperatures and high-speed driving. In hybrid and electric models, these assemblies enable energy-efficient cooling by interfacing with battery management systems, enhancing range and reducing emissions.

Performance Advantages

These wire harness assemblies deliver exceptional reliability through advanced materials and design, offering resistance to abrasion, heat, and chemical exposure common in engine compartments. Their compact and flexible construction minimizes weight and space, improving fuel efficiency while reducing electromagnetic interference for cleaner signals. This results in longer system lifespan, fewer maintenance needs, and better integration with diagnostic tools, ultimately boosting vehicle safety and performance.

Frequently Asked Questions

1. What are the key materials used in these assemblies?

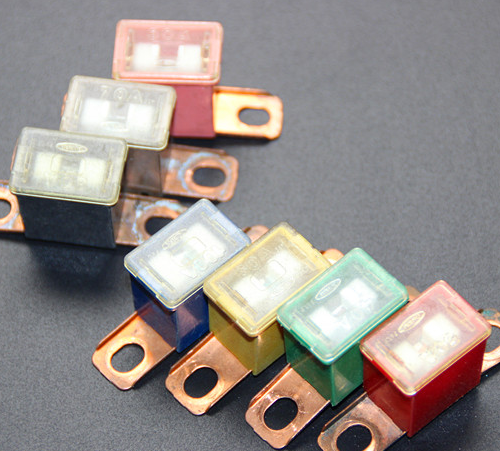

They typically incorporate high-grade copper wires with protective insulation like cross-linked polyethylene for durability and electrical efficiency.

2. How do they enhance system reliability?

By ensuring secure connections that prevent short circuits and signal degradation, they maintain consistent performance under stress.

3. Can they be customized for specific vehicles?

Yes, manufacturers provide bespoke designs to fit unique layouts and comply with industry standards like ISO 6722.