Enhancing Underhood Light Fuse Protection Against Engine Bay Overloads

News 2025-11-17

The underhood light fuse plays a small but strategic role in modern automotive electrical architecture. By isolating the engine bay light circuit from the rest of the vehicle wiring, it prevents localized overloads from cascading into larger failures. A correctly specified fuse ensures the engine compartment lamp operates safely when technicians inspect belts, hoses, and fluid levels at night or in poorly lit workshops. Without this simple protective element, a stuck switch, corroded connector, or damaged wire could overheat, melt insulation, or even ignite nearby components.

Function of the underhood light fuse in the engine bay

The underhood light fuse is engineered to open the circuit when current exceeds a defined threshold, typically caused by short circuits, pinched harnesses, or internal lamp failures. Located in the main fuse or power distribution box, it protects upstream wiring looms and downstream light assemblies. Because engine bays are exposed to vibration, moisture, and temperature extremes, the fuse is calibrated to manage transient inrush currents while still reacting quickly to genuine fault conditions. This balance between sensitivity and robustness is vital in preventing wire overheating and ensuring that only the affected circuit is disabled instead of the entire lighting system.

Application scenarios in OEM and aftermarket designs

Underhood light fuses are widely used in passenger cars, light trucks, commercial fleets, and specialty vehicles where frequent engine bay access is required. OEM engineers integrate these fuses into harness architectures to support LED or halogen service lamps that aid inspection during roadside maintenance or workshop diagnostics. In aftermarket applications, installers often add auxiliary engine bay lighting for performance cars, off-road vehicles, and utility fleets. Selecting the correct fuse rating and type is critical when upgrading from halogen to low-current LED modules, as improper sizing can either cause nuisance blowing or inadequate protection. The fuse also helps maintain warranty compliance by clearly defining protected circuits.

Performance advantages and selection criteria

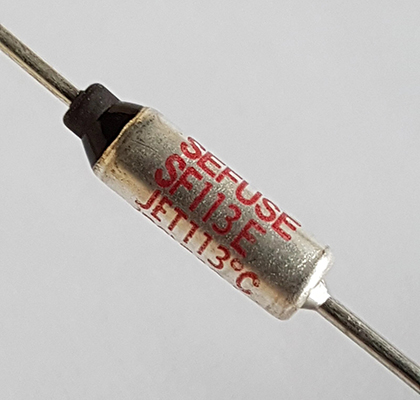

A high-quality underhood light fuse offers stable performance across a wide temperature range and repeated thermal cycling. Blade and mini-blade formats are common due to their compact footprint and ease of replacement in crowded engine compartments. Fuse characteristics such as time-current curves, interrupt rating, and voltage rating must match the vehicle’s electrical system and the specific load profile of the engine bay lamp. Superior materials and precision manufacturing reduce contact resistance and ensure consistent blow behavior, limiting the risk of intermittent faults. When combined with proper wire gauge selection and moisture-resistant connectors, the fuse significantly extends the service life of the entire lighting circuit.

Maintenance, diagnostics, and safety best practices

Technicians diagnosing an inoperative underhood light should first inspect the fuse, verifying continuity and confirming the correct amperage value. Repeated fuse failures often indicate deeper issues such as chafed insulation against metal brackets, contaminated lamp sockets, or incorrectly installed aftermarket accessories. Using manufacturer-approved fuse ratings and avoiding overspec replacements prevents hidden hazards where wires run hot without immediately failing. Routine inspection of the fuse box during scheduled maintenance, along with visual checks of engine bay harness routing, minimizes unplanned downtime and protects surrounding components such as battery cables, sensors, and control modules.

Common questions about underhood light fuses

1. Why does the underhood light fuse blow frequently?

Frequent blowing usually points to a shorted wire, water ingress in the lamp housing, or an accessory drawing more current than the circuit was designed to handle.

2. Can I increase the fuse rating to stop nuisance failures?

Using a higher rating than specified is unsafe; it may prevent the fuse from opening in time, allowing wires or connectors to overheat and sustain damage.

3. How often should the underhood light fuse be checked?

The fuse should be inspected during regular service intervals or whenever the engine bay light stops working after ruling out bulb or LED module failure.