Evaluating Thermal Stability of Wire Harnesses in High-Heat Engine Bays

News 2025-10-24

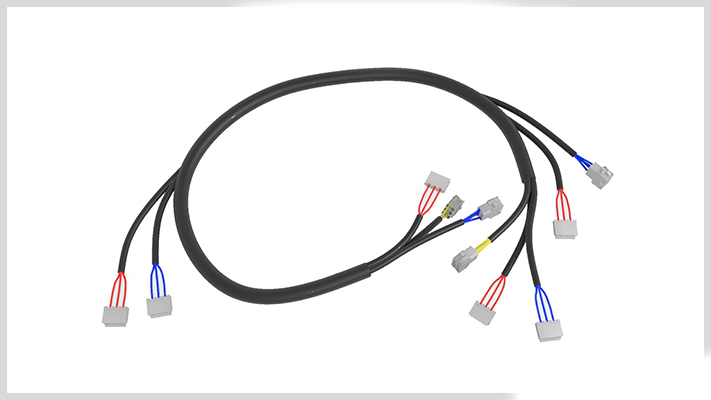

Wire harnesses serve as vital components in automotive engineering, facilitating the transmission of electrical power and signals across various systems. In the confined spaces of engine bays, where intense heat from combustion engines and exhaust systems prevails, thermal stability becomes a critical factor. This stability ensures that wire harnesses can withstand prolonged exposure to high temperatures without compromising functionality, thereby preventing issues like insulation breakdown or short circuits. As vehicles evolve with more complex electronics, understanding and optimizing thermal performance in these harsh environments is key to enhancing overall system reliability and safety.

Factors Impacting Thermal Stability

Wire harness thermal stability hinges on material selection and design choices. Insulation materials such as silicone or fluoropolymers offer high resistance to heat, maintaining flexibility and dielectric properties under stress. Conductor materials, often copper alloys, must resist oxidation and maintain conductivity. Additionally, harness layout and shielding techniques influence heat dissipation, with proper spacing and ventilation reducing thermal buildup in critical areas. These elements collectively determine how well a wire harness performs in engine bays where temperatures can exceed 100°C.

Performance Benefits in Demanding Applications

In high-heat engine bays, wire harnesses with robust thermal stability deliver significant advantages. They ensure consistent electrical performance, minimizing downtime from heat-induced failures and extending component lifespan. This reliability supports advanced automotive features, such as efficient engine control units and sensor networks, leading to better fuel economy and reduced emissions. By withstanding thermal cycles without degradation, these harnesses also contribute to safer vehicles, as they lower the risk of fires or malfunctions in extreme conditions.

Common Questions and Answers

1. What is the typical temperature range in engine bays?

Answer: Engine bays often see temperatures between 80°C and 120°C, varying with engine load and design.

2. How does thermal stability affect wire harness longevity?

Answer: It prevents material degradation, allowing harnesses to last longer and reducing the need for frequent replacements.

3. What testing methods evaluate thermal stability?

Answer: Methods include heat aging tests and thermal cycling, simulating real-world conditions to assess durability.