Expert Tips for Wire Harness Installation to Safeguard Insulation and Electrical Integrity

News 2025-10-24

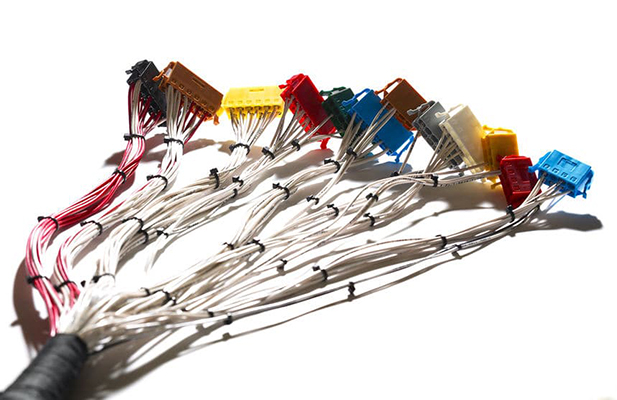

Wire harnesses are essential in electronic systems across industries like automotive and aerospace, where they bundle wires to ensure efficient power and signal transmission. Improper installation often leads to insulation damage or faulty connections, resulting in system failures, safety risks, and increased costs. This article outlines practical strategies to protect these components, focusing on real-world applications and the benefits of enhanced durability and reliability in demanding environments.

Optimal Handling Methods

In handling wire harnesses, prioritizing care prevents insulation compromise. Technicians should use tools like cable ties and protective sleeves to avoid sharp bends or abrasions, which are common in tight automotive spaces. Selecting materials with high flexibility and resistance to heat and chemicals improves performance in industrial settings, reducing the risk of electrical shorts and extending component lifespan through better material integrity.

Secure Connection Approaches

Reliable electrical connections depend on precise techniques. Using calibrated crimping tools and torque wrenches ensures connectors fit snugly without damaging wires, crucial in vibration-heavy environments like machinery. Choosing connectors with sealing features protects against moisture and dust, enhancing system efficiency and longevity by maintaining low resistance and preventing intermittent failures in critical applications.

Frequently Asked Questions

1. What causes most insulation damage during installation?

Answer: Common causes include excessive bending, improper tool use, and environmental exposure; careful handling and material selection can mitigate these.

2. How can I verify a wire harness installation?

Answer: Conduct electrical tests with a multimeter for continuity and insulation resistance, and perform visual checks to confirm no physical damage.

3. What benefits come from proper wire harness installation?

Answer: It enhances system reliability, reduces downtime, and lowers maintenance costs by preventing failures in high-stakes scenarios like automotive electronics.