Glass Fuse for Truck Battery Circuits

News 2025-10-27

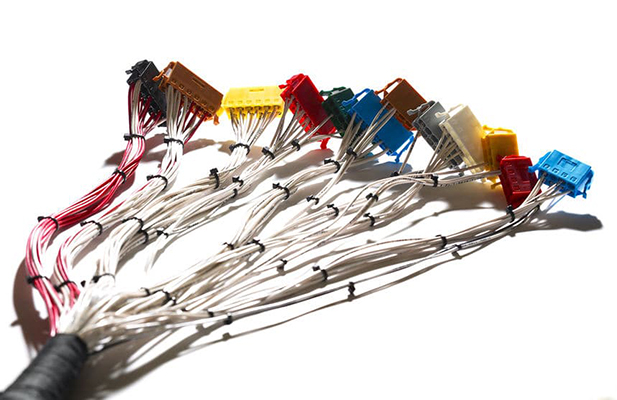

Glass fuses play a crucial role in protecting electrical systems, especially in demanding environments like truck battery circuits. These devices are designed to safeguard against overcurrent by melting a wire element when excessive current flows, preventing potential damage or fires. In the context of trucks, where battery systems must handle high power demands and endure vibrations, glass fuses offer a dependable solution. Their transparent design allows for easy visual inspection to check if the fuse has blown, which is particularly useful in field maintenance scenarios. This makes them an ideal choice for automotive applications, ensuring both safety and reliability in circuit protection.

Design and Key Specifications

Glass fuses feature a simple yet effective construction, typically consisting of a glass tube enclosing a metal wire or filament. They come in various current ratings, often ranging from a few amps to higher values suitable for truck electrical systems. The glass material provides insulation and allows users to see the fuse element clearly, aiding in quick diagnostics. Specifications include voltage ratings up to 250V or more, and they can be fast-acting or time-delay types to handle different surge conditions. In truck battery circuits, these fuses are selected based on the specific load requirements, ensuring precise protection without unnecessary interruptions.

Applications in Automotive Settings

In truck battery circuits, glass fuses are commonly installed in fuse panels to protect wiring and components from short circuits and overloads. They are particularly valuable in scenarios involving heavy-duty operations, such as powering lights, starters, or auxiliary systems. The performance advantages include high resistance to environmental factors like temperature fluctuations and moisture, which are prevalent in trucking environments. By providing fast response times to faults, glass fuses help maintain the integrity of the electrical system, reducing downtime and repair costs. This reliability makes them a preferred option for fleet operators seeking efficient circuit protection.

Frequently Asked Questions

1. What are the typical current ratings for glass fuses in trucks?

Answer: Common ratings range from 5A to 40A, chosen based on the circuit’s maximum load to ensure adequate protection.

2. How do glass fuses enhance safety in battery circuits?

Answer: Their transparent body allows immediate visual confirmation of a blown fuse, enabling quick replacement and reducing risks of electrical hazards.

3. Can glass fuses withstand the vibrations in truck operations?

Answer: Yes, they are built to endure mechanical stress and are widely used in automotive applications for their durability.