Heat-Resistant Inline Fuse Holder Featuring Nylon Housing in High-Temperature Operations

News 2026-01-12

In industrial systems exposed to high thermal loads, a heat-resistant inline fuse holder plays a vital role in safeguarding electrical circuits. Engineered with a nylon housing that withstands elevated heat levels, the component combines mechanical stability with performance consistency. Its compact inline design permits installation in confined assemblies, aiding system designers in achieving reliable overcurrent protection under challenging ambient conditions. Precise molding and quality control ensure a tight seal against dust and moisture, extending service life in demanding environments.

Applications in Elevated Temperature Zones

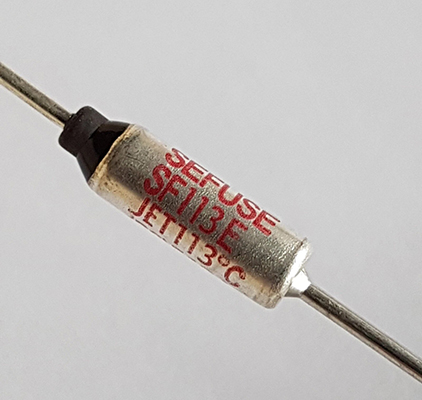

This inline fuse holder excels in power distribution modules near heat-generating elements such as resistors, transformers, and power modules. It integrates smoothly into automotive engine compartments, industrial ovens, and solar inverter cabinets. By maintaining stability at temperatures up to 130°C or higher, the nylon housing reduces the risk of deformation and electrical leakage. Such robustness makes it suitable for robotics, power conversion racks, and field service equipment operating under sustained heat stress.

Thermal Endurance and Electrical Safety

The selected nylon material exhibits a high glass transition temperature and flame-retardant properties, meeting UL94 V-0 flammability standards. Enhanced dielectric strength prevents creepage in high-voltage circuits, while an integrated silicone gasket seals the fuse chamber against contaminants. Fuses rated from 5 A to 30 A can be accommodated, ensuring consistent current limiting and safe interruption. Accurate thermal testing guarantees that the holder maintains structural integrity even during short-circuit events.

Installation Practices and Service Life Extension

Mounting options include panel clamps and cable tie slots, allowing secure fixation along power lines. Proper torque on terminal screws ensures low contact resistance and minimizes hot spots. Routine inspections should verify gasket compression and housing integrity after thermal cycling. When replacement is required, the snap-in design enables swift fuse access without disassembling surrounding modules. Careful adherence to wiring diagrams and current ratings maximizes reliability over extended operation.

1、Suitable Fuse Types

Answer: The holder supports cylindrical cartridge fuses compliant with IEC 60127-3 standards, offering a range of time-delay and fast-acting variants.

2、Operating Temperature Range

Answer: Continuous operation is rated between -40°C and +130°C, with short-term exposure up to 150°C depending on airflow conditions.

3、Recommended Maintenance Interval

Answer: Inspection of seals and contacts every 12 months is advised to maintain optimal performance under heavy thermal loads.