Heavy-Duty Thermal Fuse Enables Safe High-Power Vehicle Electrical Architecture Integration

News 2025-11-27

Heavy-Duty Thermal Fuse Supports High-Power Vehicle Electrical Applications

Thermal Protection Demands in Modern Vehicle Power Networks

High‑power vehicle platforms now integrate dense wiring harnesses, high-current DC buses, and compact power modules that operate close to thermal limits. Traction inverters, electric power steering, high-output HVAC blowers, and battery heaters all place sustained and transient loads on the electrical architecture. Under these conditions, localized overheating can arise from connector fatigue, wiring shorts, stuck relays, or silicon failure in power electronics. A heavy-duty thermal fuse provides a last‑line, non‑resettable safety element that opens the circuit once a defined temperature threshold is exceeded, preventing harness damage, thermal runaway, or fire. Unlike electronic sensing, the fuse reacts passively and does not depend on firmware, supply voltage, or communication links.

Key Performance Features and Construction Advantages

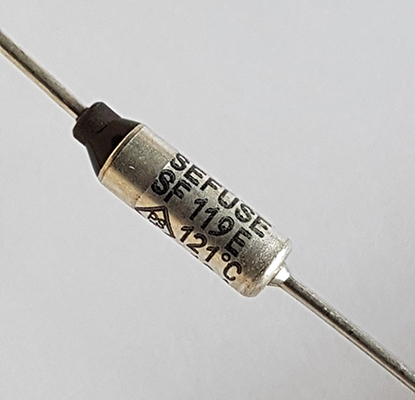

The heavy-duty automotive thermal fuse is engineered to carry currents typical of high‑power loads while maintaining tight trip-temperature tolerance. A robust, hermetically sealed body protects the fusible pellet and spring mechanism from moisture, dust, and automotive fluids, ensuring stable performance over long service life. Low contact resistance minimizes I²R losses, keeping self‑heating under control even during continuous operation near rated current. High surge tolerance supports inrush from motor start‑up or DC‑DC converter charging without nuisance opening. The fuse can be specified across multiple temperature ratings, enabling designers to select protection points tailored to specific loads, wire gauges, and ambient conditions within engine compartments, battery packs, and under‑floor zones.

Application Scenarios in ICE, Hybrid, and Battery Electric Platforms

Heavy-duty thermal fuses are increasingly deployed in traction battery heaters, coolant pumps, onboard chargers, DC‑DC converters, PTC cabin heaters, high‑power blower motors, and auxiliary power distribution units. In plug‑in hybrid and battery electric vehicles, they are often mounted in direct contact with heat‑sensitive components, such as charger transformers or power semiconductor modules, to cut power if localized hot spots occur. In traditional combustion vehicles, they protect high-wattage seat heaters, rear defoggers, and trailer power outputs. The compact package supports integration inside wiring harness junctions or molded into thermal interface assemblies so that the sensing surface closely tracks the actual component temperature rather than only the ambient air.

Design Integration, Compliance, and System-Level Benefits

When selecting a heavy-duty thermal fuse, engineers evaluate continuous current rating, maximum interrupt current, nominal functioning temperature, and tolerance against the expected thermal profile of the application. Proper derating ensures that the fuse trips only during fault or abnormal operation, not during legitimate short‑term peaks. The device can be combined with conventional current fuses or circuit breakers to create coordinated protection: the current fuse reacts to overcurrent, while the thermal fuse addresses overheating caused by degraded contacts or blocked airflow. Compliance with automotive standards on vibration, thermal shock, and flammability supports qualification in harsh environments. By incorporating this passive safeguard, vehicle manufacturers strengthen functional safety cases and increase end‑user confidence in high‑power electrical features.

FAQs on Heavy-Duty Thermal Fuses in Vehicle Applications

1. Where are heavy-duty thermal fuses typically installed in vehicles?

They are commonly installed in high‑power heater circuits, charger assemblies, battery packs, high‑current junction boxes, and near power semiconductor modules where localized overheating risk is greatest.

2. How does a thermal fuse differ from a standard current fuse?

A thermal fuse responds primarily to temperature rise at the device body, not just electrical current. It opens permanently once the internal fusible element reaches its specified functioning temperature.

3. Can a heavy-duty thermal fuse be reset after opening?

No. Once the thermal fuse operates, the circuit remains open and the component must be replaced, which confirms that the fault condition is investigated and corrected before re‑energizing the load.