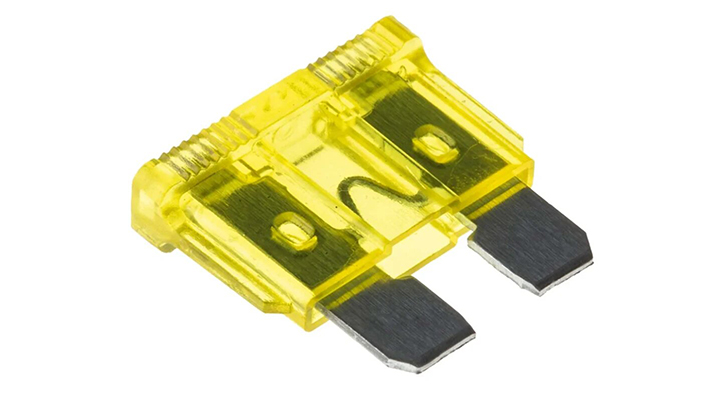

High Capacity Auto Fuse Enabling Heavy Duty Vehicle Electrical System Safety and Performance

News 2025-12-08

Large current capacity auto fuses play a decisive role in protecting the complex electrical systems used in heavy duty trucks, buses, construction equipment, agricultural machinery, and specialty utility vehicles. As onboard electronics expand to include advanced lighting, telematics, HVAC, electric power steering, and auxiliary inverters, the demand on power distribution networks increases. A properly selected high current fuse prevents harness damage, electrical fires, and costly downtime by interrupting fault currents within milliseconds while maintaining low losses during normal operation.

Key Electrical Performance Characteristics

High current auto fuses for heavy duty platforms are typically rated from 60 A up to 600 A and operate at system voltages of 12 V, 24 V, and increasingly 48 V. Low internal resistance minimizes I²R power dissipation, helping reduce hot spots around fuse blocks and battery junction boxes. Time‑current characteristics are engineered to tolerate short inrush surges from starter motors, compressors, and high‑power pumps, yet clear rapidly under sustained overloads or direct short circuits. Compliance with ISO, SAE, and OEM-specific test standards ensures consistent opening behavior, mechanical robustness, and vibration endurance in demanding environments.

Application Scenarios in Heavy Duty Vehicles

These fuses are widely deployed in battery distribution units, power take‑off systems, winch circuits, hydraulic pump drives, and high‑capacity auxiliary power outlets. In long‑haul trucks and coaches, large current fuses protect inverter‑driven hotel loads, refrigeration units, and advanced infotainment systems. Construction and mining vehicles rely on them to secure high‑torque electric drives and centralized lighting rigs subject to dust, shock, and wide temperature swings. Agricultural equipment uses them to safeguard precision farming controllers, electro‑hydraulic valves, and telematics modules that must stay operational throughout long, remote working hours.

Design Advantages and Selection Considerations

Modern high current auto fuses feature compact footprints compatible with modular fuse and relay boxes, enabling dense packaging near the battery or power distribution center. Copper or copper alloy elements, combined with high‑temperature, flame‑retardant housings, deliver stable performance under continuous high load. Designers typically consider continuous current rating at elevated ambient temperature, voltage rating, interrupting capacity, and mounting style such as bolt‑down or plug‑in. Correct coordination between the fuse rating and cable cross‑section ensures that conductors remain protected while limiting nuisance trips caused by transient surges during normal equipment start‑up.

Installation, Maintenance, and Safety Benefits

Proper installation of large current auto fuses improves both system uptime and serviceability. Positioning the fuse close to the power source reduces the length of unprotected cable, lowering fire risk in case of insulation damage. Clear marking of ratings, circuit function, and torque specifications supports quick replacement in fleet workshops. Periodic inspection for corrosion, loose hardware, or discoloration helps maintain low contact resistance and stable temperature rise. When combined with structured preventive maintenance, these fuses significantly cut the likelihood of catastrophic harness failures, unplanned stops, and costly vehicle recovery operations.

1. What current ratings are common in heavy duty vehicle auto fuses?

They typically range from 60 A to 600 A, selected according to cable size, load profile, and system voltage.

2. Where should large current fuses be installed in a heavy duty electrical system?

They are usually placed near the battery or main power distribution point to protect downstream harnesses and major loads.

3. How do time‑current curves affect fuse selection?

Time‑current curves help ensure that the fuse tolerates short inrush peaks from motors and compressors while still opening quickly under sustained overloads or short circuits.