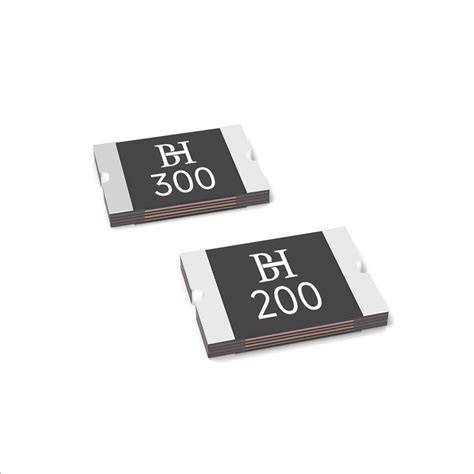

High-Precision Thermal Fuse Triggers Accurately at Preset Temperature Thresholds in Demanding Circuits

News 2025-11-27

High-precision thermal fuses play a decisive role in preventing overheating damage in compact, high-power electronic systems. Unlike resettable protectors, these single-action devices permanently open the circuit once a preset temperature is reached, ensuring a clear, fail-safe interruption. Their tight tolerance around the rated temperature makes them a preferred choice in applications where a few degrees can determine product safety, lifetime, and compliance.

Principle of Operation and Key Design Features

A high-precision thermal fuse contains a temperature-sensitive pellet or alloy element that reacts sharply at a calibrated threshold. When the internal temperature reaches the rated value, the element changes state, releases mechanical tension, and separates the current-carrying contacts. High-quality devices maintain narrow trip tolerances, often within ±3–5 °C, across the specified range. Critical parameters include rated functioning temperature, holding temperature, maximum open-circuit voltage, interrupting current, and insulation resistance. Robust housings and lead configurations support automated assembly, reflow or wave soldering, and long-term stability under repeated thermal cycling.

Performance Advantages in Modern Power Electronics

Compared with bimetal thermostats or PTC resettable protectors, high-precision thermal fuses provide a clean, non-arcing opening at the exact predefined temperature, unaffected by gradual drift or mechanical fatigue. Their compact size and low series resistance minimize losses in high-efficiency designs such as GaN and SiC power stages. Fast thermal response enables rapid disconnection during fault conditions, protecting transformers, chargers, LED drivers, and DC‑DC converters from thermal runaway. Many series are certified under UL, VDE, and IEC standards, helping manufacturers meet strict safety and energy regulations while shortening approval cycles.

Application Scenarios in High-Density and Safety-Critical Systems

High-precision thermal fuses are widely integrated into battery packs, EV on-board chargers, household appliances, medical instruments, and industrial control cabinets. In lithium-ion battery modules, they are often placed close to high-current bus bars or cell groups to disconnect the pack if an internal fault raises the temperature beyond the safe window. In SMPS power supplies and adapters, they are mounted near transformers, PFC chokes, or MOSFET heat sinks to prevent insulation breakdown and fire hazards. White goods, such as dryers, dishwashers, and induction cookers, rely on thermal fuses as an independent hardware safety layer, even when microcontroller-based temperature monitoring is already present.

Selection Considerations and Integration Best Practices

Engineers should match the fuse’s rated functioning temperature to the worst-case hotspot expected in the application, keeping sufficient margin above the highest normal operating temperature but below any level that could damage nearby materials. Proper thermal coupling, using clips, epoxy, or direct contact on heat spreaders, is crucial to achieve accurate triggering. Designers must verify that the fuse’s voltage and interrupting current ratings exceed the maximum fault conditions of the system. Layout should avoid mechanical stress on the leads and allow clear creepage and clearance distances. Documenting the fuse’s position and thermal environment during safety testing helps prove compliance during certification.

Brief Q&A on High-Precision Thermal Fuses

1How does a thermal fuse differ from a thermostat?

A thermal fuse opens the circuit once and remains permanently open, acting as a non-resettable safety link, while a thermostat cycles on and off to regulate temperature.

2Where should a high-precision thermal fuse be placed in a power supply?

It should be mounted near the primary heat source, such as the transformer or primary switching devices, ensuring tight thermal coupling to the component that represents the worst-case hotspot.

3Can a thermal fuse replace electronic overtemperature protection?

It should not replace active protection; it is best used as a final safety mechanism backing up sensors, firmware, and control circuitry in case those layers fail.