How to Choose a Car Fuse Holder for Extreme Cold Climates: Key Considerations and Tips

News 2025-10-20

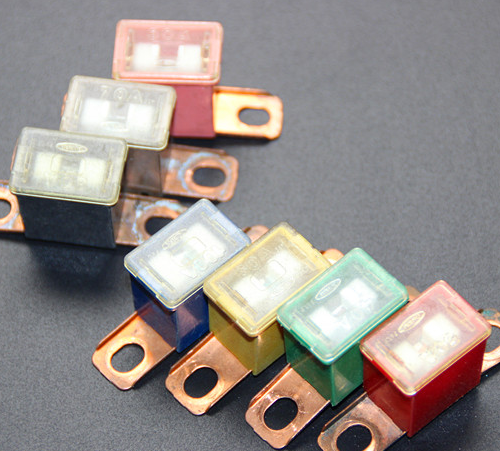

In extreme cold climates, such as those in the Arctic or mountainous regions, automotive electrical systems face severe challenges that can compromise safety and performance. A car fuse holder is critical for protecting circuits by securely holding fuses that prevent overloads. Cold temperatures can cause materials to brittle, reduce conductivity, and allow moisture ingress, leading to failures. Selecting the right fuse holder ensures reliable operation in harsh conditions, safeguarding vehicles used in winter sports, emergency services, or daily commutes in snowy areas. This guide focuses on essential factors for making an informed choice.

The Impact of Cold Temperatures on Fuse Holders

Cold weather significantly affects fuse holder components, with plastics becoming brittle and metals contracting, which can disrupt electrical contacts and cause overheating. In subzero conditions, ice buildup may compromise seals, leading to short circuits or corrosion. High-quality fuse holders use resilient materials like polycarbonate or rubber gaskets that maintain flexibility and integrity down to -50°C. Understanding these effects helps identify products that minimize risks, ensuring consistent protection in freezing environments where reliability is paramount.

Essential Features for Cold-Climate Fuse Holders

When selecting a fuse holder for extreme cold, prioritize features that enhance durability and performance. Look for wide temperature ranges, typically -40°C to 125°C, and high IP ratings like IP67 for superior dust and water resistance against snow and ice. Materials such as corrosion-resistant alloys or UV-stabilized plastics prevent degradation, while secure mounting options reduce vibration-induced failures in rough terrains. These attributes not only extend lifespan but also improve energy efficiency and safety in demanding applications.

Real-World Applications and Benefits

Fuse holders designed for cold climates excel in scenarios like off-road vehicles in tundra regions or fleet operations in wintery conditions, where electrical failures can be costly or dangerous. For example, in ambulances or snowplows, these holders ensure critical systems function without interruption. Benefits include reduced maintenance needs, lower failure rates, and enhanced vehicle longevity, making them ideal for industries relying on uninterrupted power. By choosing appropriately, users gain peace of mind and optimized performance in adverse weather.

1. What temperature range should a fuse holder handle in cold climates?

Answer: It should operate reliably from at least -40°C to ensure it doesn’t fail in freezing conditions.

2. How does material choice affect fuse holder performance in winter?

Answer: Durable materials like silicone resist cracking and maintain seals, preventing moisture damage and ensuring consistent conductivity.

3. Why are sealed fuse holders important for extreme cold?

Answer: Sealing protects against ice and snow infiltration, reducing the risk of short circuits and extending the component’s lifespan in harsh environments.