Ignition Fuse Solutions That Protect Automotive Ignition System Components From Electrical Damage

News 2025-11-17

Modern vehicles depend on precisely controlled ignition systems to ensure efficient combustion, low emissions, and reliable engine start-up. Within these systems, the ignition fuse plays a key protective role, isolating sensitive components from overcurrent, wiring faults, and short circuits. By interrupting abnormal current flow in milliseconds, the ignition fuse helps maintain system stability, reduces maintenance costs, and extends the overall lifespan of ignition coils, ECUs, and related control electronics.

Core Function and Working Principle

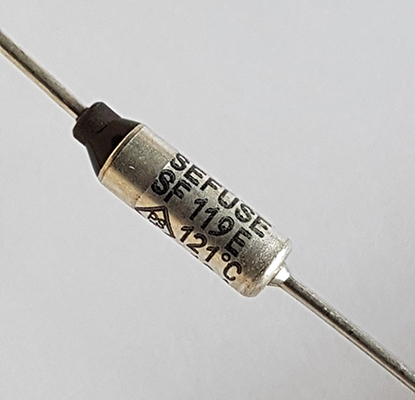

The ignition fuse is designed as a sacrificial element placed in series with the ignition circuit. Under normal operating conditions, it carries the rated current to ignition coils, control modules, sensors, and relays without significant power loss. When a fault such as a shorted coil, damaged harness, or internal ECU failure causes current to rise beyond the specified threshold, the fuse element rapidly heats and melts, creating an open circuit. This fast interruption prevents overheating of wiring insulation, connector damage, and catastrophic failure of high-value electronics. Selecting the correct current rating, voltage rating, and time–current characteristic is therefore fundamental to providing effective protection.

Key Performance Advantages

High-quality ignition fuses offer stable breaking capability, tight tolerance on rated current, and controlled I²t behavior to match the dynamic load of modern ignition systems. Fast-acting designs limit peak fault energy and reduce the risk of thermal runaway in compact engine bays. Low resistance materials minimize voltage drop, which helps maintain strong spark energy under high load conditions. Robust ceramic or high-temperature polymer housings improve vibration resistance and withstand harsh under-hood temperatures, moisture, and contamination. These performance features translate into higher engine start reliability, fewer unexpected breakdowns, and optimized protection of ignition drivers and engine control units.

Application Scenarios in Modern Vehicles

Ignition fuses are widely used in passenger cars, commercial trucks, motorcycles, small engines, and hybrid powertrains. In conventional gasoline engines, they protect the power feed supplying ignition coils and control modules. In turbocharged and downsized engines, higher ignition energy and more complex wiring layouts increase the importance of accurate fuse coordination. Hybrid and start-stop systems place additional cycling stress on ignition components, making stable overcurrent protection crucial to prevent nuisance failures. Ignition fuses are also integrated into dedicated fuse boxes, power distribution centers, and smart junction blocks, enabling OEMs to implement modular, easily serviceable protection solutions that support rapid troubleshooting and replacement.

Selection Considerations and Design Integration

Engineers must evaluate load profiles, peak inrush current, ambient temperature, and available fault current when selecting an ignition fuse. Coordination with upstream supply fuses and downstream electronic protection devices avoids overlapping characteristics and unwanted tripping. Proper PCB or harness layout ensures minimal contact resistance and secure mechanical retention under vibration. Using standardized automotive fuse formats such as mini-blade, micro-blade, or bolt-on high-current types helps streamline assembly and simplify field service. Compliance with automotive standards such as ISO and SAE specifications confirms that the fuse can withstand thermal cycling, corrosive environments, and long-term electrical stress in demanding ignition applications.

Application Benefits and Maintenance Impact

From a maintenance perspective, ignition fuses provide a clear and easily diagnosable failure point. In the event of an overcurrent event, technicians can quickly identify a blown fuse, trace the underlying circuit fault, and restore system operation by replacing a low-cost component instead of an entire ignition module. This approach substantially decreases repair time and protects the vehicle owner from costly component replacements. In fleet vehicles and heavy-duty applications, optimized ignition fuse strategies contribute to improved uptime, predictable service intervals, and lower total cost of ownership.

1. Why does an ignition system need a dedicated fuse?

A dedicated ignition fuse isolates faults in the ignition circuit, preventing overheating, wiring damage, and ECU failure, while keeping the rest of the electrical system stable.

2. How is the proper ignition fuse rating determined?

The rating is selected based on normal operating current, expected inrush, ambient temperature, and fault current levels, ensuring fast interruption of dangerous overloads without nuisance blowing.

3. What symptoms indicate a possible ignition fuse problem?

Common indicators include no-start conditions, loss of spark, intermittent stalling, and a fuse that repeatedly blows after replacement, signaling an underlying wiring or component fault.