Industrial Wire Harness Designs for Agricultural Machinery Electrical Systems

News 2025-10-31

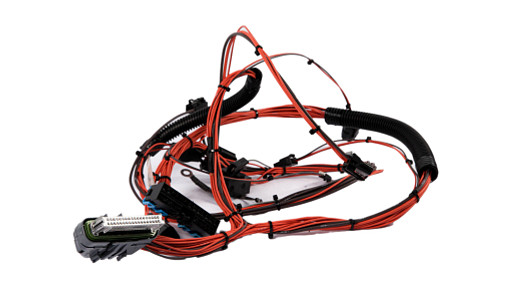

In agricultural machinery, electrical systems are vital for powering components like engines, sensors, and control units, enhancing productivity and precision farming. Wire harness designs serve as the backbone, bundling wires and connectors to manage complex circuitry efficiently. These designs must address challenges such as vibration, moisture, and temperature extremes typical in farming environments. By optimizing wire routing and connection integrity, they reduce the risk of electrical failures, ensuring machinery operates reliably during long hours in the field.

Application Scenarios

Wire harnesses are integral in various agricultural machines, including tractors and harvesters. In tractors, they connect the dashboard controls to hydraulic systems and GPS modules, facilitating seamless operation in diverse terrains. For harvesters, harness designs support automated features like yield monitoring and steering assistance, improving efficiency during harvest seasons. These applications demand custom designs that accommodate space constraints and integrate with existing mechanical structures, making wire harnesses essential for modern, tech-driven agriculture.

Performance Advantages

Key benefits include enhanced durability through the use of robust materials that resist corrosion and abrasion. This ensures longevity in harsh conditions, such as exposure to dust, chemicals, and varying weather. Additionally, optimized designs minimize electrical resistance, leading to better energy efficiency and reduced heat generation. By streamlining installation and maintenance, these harnesses lower downtime costs for farmers, while their modular nature allows for easy upgrades, adapting to evolving technological needs in agricultural equipment.

Frequently Asked Questions

1. What materials are commonly used in wire harnesses for agricultural machinery?

Wire harnesses often incorporate PVC or XLPE insulation for flexibility and heat resistance, along with metal connectors that provide strong, corrosion-resistant joints to handle outdoor conditions.

2. How do wire harness designs improve safety in agricultural equipment?

They reduce the risk of short circuits and wire damage by organizing cables neatly, preventing exposure to moving parts and environmental hazards, thus enhancing overall machine safety.

3. What factors should be considered when customizing a wire harness?

Key factors include the specific machinery layout, environmental exposure, voltage requirements, and integration with electronic controls to ensure optimal performance and reliability.