Inline Fuse Holder Strain Relief Ensures Vibration Durability

News 2026-01-12

Inline fuse holders equipped with an integrated strain relief have emerged as a vital component in applications subject to mechanical vibration. Traditional fuse holders often rely on standard wire terminations that can loosen under repeated oscillation, leading to premature wire breakage and potential circuit failures. The advanced strain relief design secures conductors at the entry point, reducing stress concentration and preserving electrical continuity. Manufacturers tailor these assemblies to meet stringent industry standards while addressing evolving reliability demands.

Design Features

Strain relief-enabled inline fuse holders incorporate thermoplastic housings treated for high flame resistance and UV stability. The internal jaws clamp conductors firmly without deforming insulation, while a ribbed entry port prevents axial movement. Contacts are silver or tin plated, offering low insertion loss and corrosion resistance. Fuse cartridges slide into a solvent-resistant chamber that seals against dust and moisture. Engineers specify precise clamp tension and optimized wire retention angles to withstand continuous vibration amplitudes in harsh environments.

Application Scenarios

These fuse holders excel across automotive electronics, heavy machinery, and marine systems where vibration poses a significant risk. They serve power distribution panels in off-road vehicles, dashboard assemblies in commercial trucks, and control cabinets in industrial conveyor setups. Marine navigation and communication modules benefit from sealed fuse compartments that resist salt spray. Renewable energy inverters and robotics installations also rely on these devices to safeguard circuits under dynamic loads. Custom wire gauges and fuse ratings enhance flexibility for diverse installation trials.

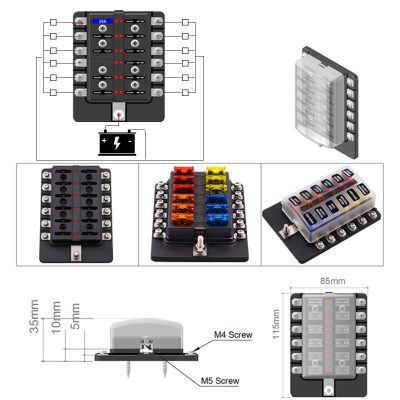

Installation and Maintenance

Mounting the inline fuse holder requires minimal tooling: secure the unit to a panel using compatible fasteners, strip the wire to the recommended length, and insert conductors until they lock in place. Fuse replacement is quick—press the release tab to extract the holder, swap cartridges, and reinsert. Periodic inspections confirm strain relief integrity and contact cleanliness. Maintenance guidelines recommend torque specifications for clamp screws and routine checks under load to prevent thermal degradation over extended service cycles.

1、What material is used in these holders?

Answer: Molded high-temp thermoplastic rated UL 94 V-0 provides flame retardance, UV and oil resistance, plus durable flexibility under repeated vibration.

2、How does strain relief extend circuit life?

Answer: By securing conductors at the cable entry, stress concentrates away from terminations, reducing metal fatigue and preventing wire fractures during ongoing vibration.

3、What voltage and current options exist?

Answer: Available in 12V, 24V, and 32V DC ranges up to 30A; select models support AC voltages to 600V and currents beyond 50A.