Inline Fuse Holder Wiring Diagram Ensuring Correct Polarity in 12V/24V Systems

News 2026-01-12

In direct current systems, installing an inline fuse holder with correct polarity delivers reliable protection against overloads and shorts. Accurate orientation of positive and negative conductors prevents reverse current flow that could damage electronics or starter motors in automotive 12V systems and voltage regulators in 24V industrial setups. Following detailed wiring diagrams and observing color-coded cable standards guarantees consistent voltage reference throughout each circuit segment. These practices minimize diagnostic time and ensure maintenance teams can quickly identify and replace faulted conductors, enhancing uptime in any DC power installation.

Application Scenarios

Inline fuse holders appear in a wide range of scenarios where compact, field-serviceable circuit protection is required. In automotive environments, 12V dashboards, LED lighting, and engine management modules rely on quick-access fuse holders mounted within wiring harnesses. Marine applications utilize sealed fuse assemblies to protect 24V trolling motors, navigation equipment, and bilge pumps from saltwater corrosion. Off-grid solar systems incorporate inline fuses to isolate string combiners and prevent backfeeding into charge controllers during nighttime operation. Industrial sensor networks and rack-mounted telecom gear also benefit from standardized inline protection, streamlining both installation and field diagnostics.

Performance Benefits

Implementing correct polarity in inline fuse holder wiring enhances both safety and efficiency. Positioning the fuse on the positive conductor ensures that an overcurrent event interrupts power before it can propagate to sensitive modules, motors, or battery management systems. Maintaining proper conductor orientation helps limit voltage drop across the protective element, which reduces heat generation under continuous loads. Color coding and adherence to wiring diagram conventions accelerate troubleshooting by allowing technicians to trace live and neutral conductors instantly. These measures prolong component life and reduce the risk of unplanned downtime in demanding 12V or 24V installations.

Wiring Best Practices

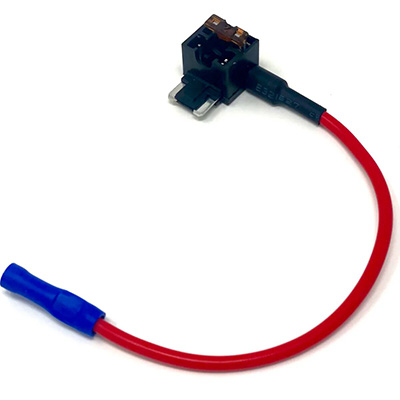

Select the appropriate wire gauge and fuse rating by calculating peak inrush currents, ambient temperature effects, and potential derating factors. Standardize positive leads in red and negative leads in black or blue, and use heat-shrink tubing or cable markers to reinforce polarity identification. Secure contacts with quality crimp terminals or solder joints, and torque screw-type fuse holders per manufacturer specifications to prevent loosening under vibration. Mount fuse holders away from heat sources, moisture ingress points, or areas subject to physical damage. Always verify polarity alignment with a digital multimeter before energizing the circuit to confirm that the inline protection will operate as designed.

1、How does correct polarity improve fuse protection?

Correct wiring orientation places the fuse on the positive path, ensuring overloads interrupt power before reaching sensitive loads and preventing damage.

2、Is it safe to mix 12V and 24V fuse holders?

Only when each holder is explicitly rated for the system voltage; mismatched voltage ratings risk arcing and equipment failure.

3、Which wire gauge works best for a 10A inline fuse?

Typically, 16 AWG wire handles up to 10 amps in DC circuits, but selecting gauge should account for length, temperature, and regulatory requirements.