Key Performance Differences Between OEM And Generic Automotive Fuse Box Components

News 2025-12-26

In modern vehicles, the fuse box is a central protection hub that safeguards power distribution to ECUs, sensors, lighting, infotainment, and safety systems. As fleets age and cost pressure rises, many maintenance teams weigh original equipment manufacturer (OEM) fuse boxes against generic aftermarket versions. Evaluating not only price but also thermal behavior, contact integrity, diagnostics, and long‑term reliability is crucial for designers, purchasing engineers, and workshop managers focused on uptime and warranty risk.

Construction Quality And Electrical Performance

OEM fuse boxes typically use higher‑grade copper alloys, plated contacts, and engineering plastics rated for elevated temperatures and vibration. This results in lower contact resistance, more stable voltage delivery, and less heat buildup under continuous load. Generic units may meet basic current ratings on paper yet show greater variation in terminal spring force or plating thickness, increasing the chance of micro‑arcing and localized hot spots. In high‑load circuits such as electric power steering, HVAC blowers, or heated seats, these small differences can translate into fuse fatigue, intermittent faults, or melted housings.

Compatibility, Integration, And Application Scenarios

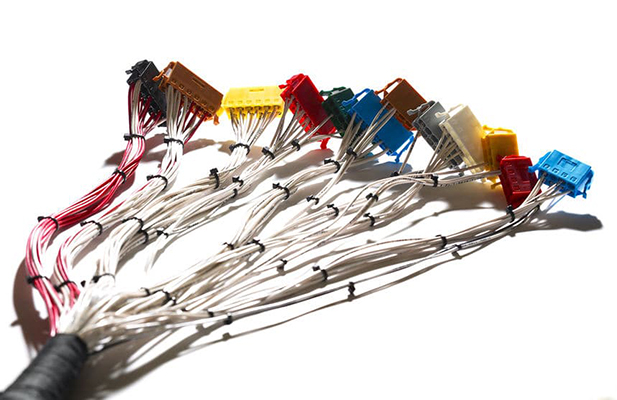

OEM fuse boxes are engineered to match vehicle‑specific wiring harness geometry, CAN or LIN gateway modules, and mounting points. In applications like commercial trucks, emergency vehicles, and high‑density EV architectures, this precise integration supports predictable current paths and clean EMI behavior. Generic parts may rely on universal layouts, adapters, or modified terminals, which can stress harness connectors or introduce unintended resistance. For high‑duty cycles, fleet telematics units, and auxiliary power systems, exact circuit mapping and connector alignment strongly influence diagnostic accuracy and downtime.

Durability, Environmental Stress, And Safety Margins

OEM assemblies are usually validated through salt‑spray tests, thermal cycling, vibration profiles, and humidity exposure tailored to the platform’s target markets. Their creepage distances, flame ratings, and derating curves support consistent performance under under‑hood temperatures, voltage spikes, and cold‑start conditions. Some generic fuse boxes are only tested to minimal bench standards, lacking documented performance under combined stress. In harsh applications such as off‑road machinery, refrigerated transport, and high‑altitude operation, limited validation can manifest as cracked housings, corroded busbars, or nuisance fuse blow events that compromise safety and regulatory compliance.

Cost, Lifecycle Value, And Maintenance Strategy

Generic fuse boxes often deliver immediate purchase savings, attractive for independent workshops and budget repairs on older vehicles. However, when factoring repeat labor, troubleshooting time, and potential damage to downstream ECUs, OEM units often provide better total cost of ownership. For mission‑critical fleets, public transport, and premium EV platforms where unplanned outages are expensive, the predictable behavior and documented specifications of OEM fuse boxes align better with planned maintenance schedules. Strategic use of OEM components in high‑load or safety‑related circuits, combined with careful selection of higher‑quality generics in low‑risk zones, can balance cost and performance.

1、Are generic fuse boxes safe in high‑current applications?

Safety depends on material quality, contact design, and tested temperature rise. In high‑current zones such as starter feeds or high‑power inverters, OEM units usually offer stronger validation and wider safety margins.

2、Do OEM fuse boxes improve diagnostic accuracy?

Yes. OEM designs match the original wiring diagrams and module interfaces, which simplifies fault tracing using factory diagnostic tools and reduces misinterpretation of intermittent issues.

3、When does a generic fuse box make practical sense?

Generic parts can be practical for aging vehicles in low‑load, non‑safety‑critical circuits where cost control is a priority and minor variations in performance have limited operational impact.