Key Techniques for Glass Fuse Replacement in Truck Electrical Systems

News 2025-10-27

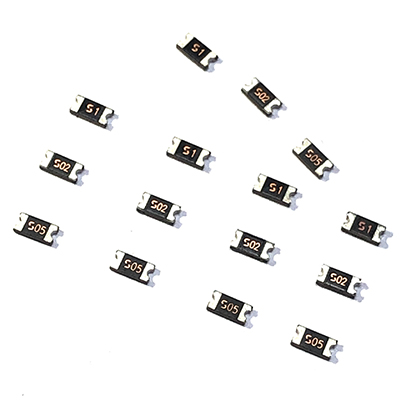

Glass fuses play a critical role in protecting truck electrical systems from overloads and short circuits, ensuring reliable operation in demanding environments. These components safeguard vital circuits in vehicles like heavy-duty trucks, where electrical failures can lead to costly downtime. By understanding the specifics of glass fuse replacement, truck owners and technicians can maintain optimal performance and prevent potential hazards on the road.

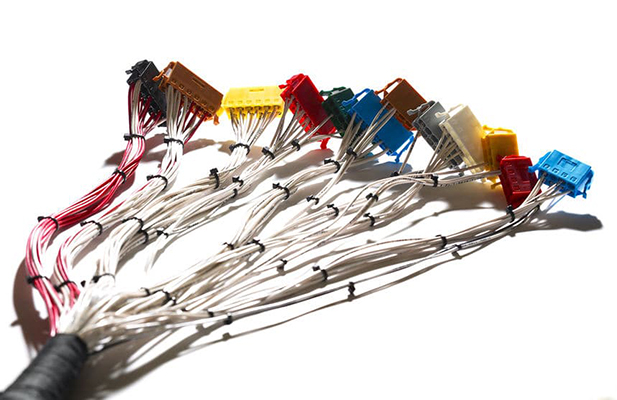

Glass fuses are widely used in truck electrical setups for protecting components such as lighting, ignition, and accessory circuits. In scenarios involving long-haul transport or off-road conditions, these fuses handle vibrations and temperature fluctuations effectively, making them ideal for battery management and wiring harnesses. Their compact design allows easy integration into tight spaces within truck dashboards and engine compartments, enhancing overall system efficiency.

One major advantage of glass fuses is their fast response to electrical faults, which minimizes damage to sensitive truck electronics. They offer precise current ratings that improve energy efficiency and reduce the risk of fires in high-power applications. Compared to other fuse types, glass fuses provide clear visual indicators of failure, allowing for quick diagnostics and replacements during maintenance routines.

1. How do I identify a blown glass fuse?

Answer: Look for a broken filament inside the glass tube or discoloration; test with a multimeter for continuity.

2. What tools are needed for fuse replacement?

Answer: You’ll need a fuse puller, replacement fuses of the correct rating, and a wiring diagram for your truck model.

3. Can glass fuses be reused?

Answer: No, once a glass fuse blows, it must be replaced to ensure proper protection and avoid electrical risks.