Lockable Battery Box Lids That Secure Power Systems From Unauthorized Access

News 2025-11-17

Lockable battery box lids play a central role in power system safety, asset protection, and regulatory compliance. From small mobility devices to large-scale energy storage cabinets, restricting physical access to batteries reduces the risk of accidental contact, tampering, and theft. A well‑designed lockable lid not only protects the cells but also preserves the integrity of the entire electrical system, improving uptime and lowering maintenance costs.

Key Design Features and Construction

A modern lockable battery box lid combines mechanical strength with user‑oriented functionality. Typical constructions use impact‑resistant ABS, polycarbonate, or powder‑coated steel, paired with stainless‑steel hinges and corrosion‑resistant latches. Gasketed seals support IP‑rated protection against dust and moisture, helping battery packs maintain stable performance in harsh outdoor or marine environments. Integrated keyed or padlock‑ready latch mechanisms ensure that only authorized technicians can open the enclosure, while reinforced corners and internal ribs help withstand vibration and shock loads common in automotive, off‑grid, and industrial settings.

Application Scenarios Across Industries

Lockable lids are widely deployed wherever battery integrity is mission‑critical. In boats and RVs, sealed and lockable battery boxes keep terminals away from passengers, pets, and loose metallic objects that might cause short circuits. Telecom cabinets and base stations use lockable enclosures to prevent vandalism and unauthorized replacement of high‑value backup batteries. In solar energy storage systems, a lockable lid restricts access to high‑capacity lithium or lead‑acid banks while allowing technicians to perform inspections through side ports or removable panels. Material‑handling equipment, floor scrubbers, and mobility scooters also benefit from secure battery compartments that deter tampering in public spaces.

Performance Advantages and Safety Benefits

Lockable battery box lids offer performance advantages that extend beyond simple security. By maintaining a controlled environment around the cells, these lids help stabilize temperature and reduce exposure to contaminants, which can extend battery service life. Secure latching prevents accidental opening during transport or operation, minimizing the risk of acid spills, arcing, or damaged terminals. Many designs integrate cable strain reliefs, venting channels, and clear labeling zones, supporting neat wiring layouts and easy identification of battery data. The combination of mechanical protection and access control supports compliance with marine, automotive, and industrial safety standards, which is increasingly important for OEMs and system integrators.

Selection, Installation, and Maintenance Considerations

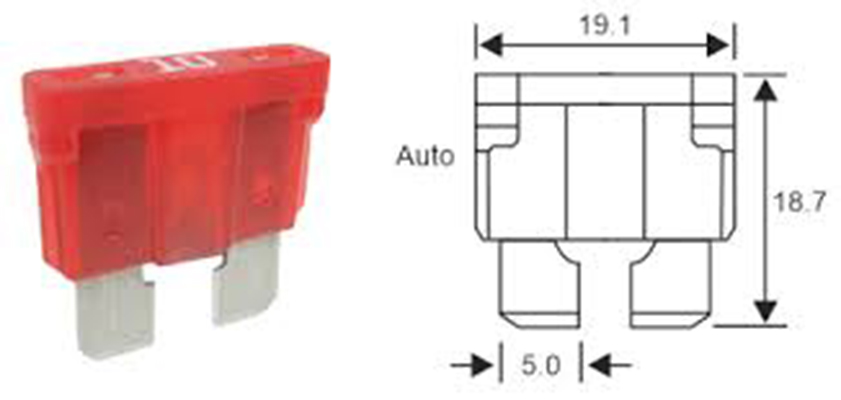

Choosing a lockable lid requires careful evaluation of battery form factor, enclosure footprint, and installation environment. Engineers should verify internal clearance for cabling, fuses, and monitoring electronics, and confirm that the chosen locking mechanism aligns with the site’s key management policy. For outdoor or marine use, UV‑stable materials, wide‑temperature ratings, and robust sealing are essential. During installation, the lid and box should be mounted to rigid structures with appropriate fasteners, and strain relief should be applied to all leads exiting the enclosure. Regular inspection of hinges, locks, seals, and vent paths helps maintain long‑term safety and performance.

FAQ

1. How does a lockable battery box lid improve safety?

A lockable lid limits physical access to live terminals, reducing the risk of accidental contact, short circuits, and unauthorized modifications in both commercial and residential installations.

2. Where are lockable battery box lids most commonly used?

They are frequently used in marine vessels, RVs, solar energy storage systems, telecom cabinets, industrial machinery, and mobility equipment deployed in public or semi‑public areas.

3. What features should engineers look for when specifying a lid?

Key factors include material strength, IP or NEMA protection rating, lock type, corrosion resistance, thermal and venting design, and compatibility with the target battery size and cabling layout.