Long-Lasting Wire Harness Assemblies for Automotive Battery Management

News 2025-10-31

Wire harness assemblies are fundamental to the reliability of automotive electrical systems, particularly in managing batteries for electric and hybrid vehicles. They consolidate multiple wires and connectors to ensure efficient power transmission and data exchange, which is vital for monitoring battery health, preventing failures, and supporting the shift towards sustainable transportation. As vehicles become more complex, these assemblies must endure extreme conditions like vibrations, temperature variations, and chemical exposures to maintain performance over time.

Applications in Vehicle Systems

In electric vehicles, wire harness assemblies link battery cells to management controllers, enabling real-time tracking of charge levels and thermal states to optimize energy use. They also connect components in hybrid systems, facilitating seamless integration between electric and traditional engines. Additionally, in fleet operations such as delivery trucks or public transport, these harnesses support diagnostic tools and energy-efficient routing, helping to minimize downtime and extend operational efficiency.

Performance Advantages

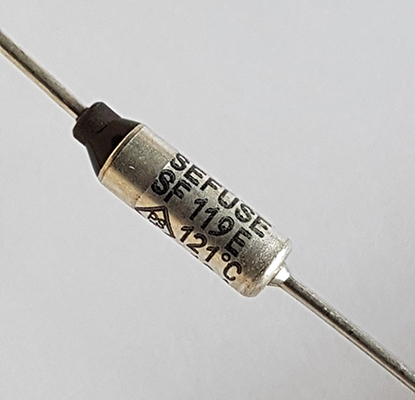

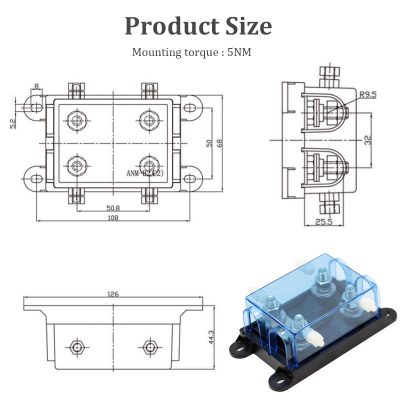

Constructed with advanced materials like high-temperature-resistant polymers and corrosion-proof metals, wire harness assemblies offer exceptional durability against wear and environmental factors. Their design reduces electrical resistance, leading to lower heat generation and improved energy efficiency in battery systems. This robustness ensures consistent connectivity, reducing the risk of faults that could affect vehicle safety or battery longevity in demanding automotive scenarios.

Frequently Asked Questions

1、What is a wire harness assembly?

A wire harness assembly is a bundled set of wires, connectors, and terminals that organize and protect electrical connections within a vehicle, simplifying installation and maintenance.

2、How do they improve battery management systems?

They provide reliable pathways for power and data, allowing precise control and monitoring of battery functions to enhance efficiency, safety, and overall vehicle performance.

3、What makes these assemblies long-lasting?

Factors include the use of durable materials, sealed designs to prevent moisture entry, and engineering that withstands mechanical stress, ensuring sustained reliability in automotive applications.