Low-Amperage Fuse Solutions Enhancing Protection of Delicate In-Vehicle Electronics

News 2025-11-17

In modern vehicles, low-amperage fuses play a decisive role in safeguarding increasingly delicate electronic modules and signal circuits. Advanced driver assistance systems, infotainment platforms, telematics units, and sensor networks rely on stable low-current power rails that must be protected from micro-short events and transient overloads. Correctly specified low-amperage fusing not only prevents catastrophic damage to high-value control units, it also stabilizes system performance, reduces intermittent faults, and supports stringent automotive safety and EMC standards.

Key functions and performance characteristics

Low-amperage fuses are engineered to open precisely at rated currents in the range of milliamps to a few amps, providing finely tuned circuit protection. Their time-current curves are optimized to withstand harmless inrush currents of ECUs and sensors while cutting off sustained overloads that could overheat delicate traces or connectors. Automotive-grade versions feature tight tolerance on melting I²t, consistent resistance values to minimize voltage drop, and robust arc suppression to avoid collateral damage on densely packed PCBs. Compliance with AEC-Q200 and ISO electrical test requirements ensures long-term stability under thermal cycling, vibration, and humidity.

Application scenarios in sensitive vehicle circuits

Typical applications include protection of CAN, LIN, and FlexRay transceivers, radar and camera modules, position and pressure sensors, and low-current LED lighting strings. These nodes often operate at low voltage and low current, making them vulnerable to subtle overcurrent events caused by wiring harness chafing or connector contamination. Low-amperage fuses installed close to the load isolate faulted branches quickly, helping maintain communication bus integrity and preventing a single local failure from propagating into the main power distribution system. In EV and hybrid platforms, they are widely used in BMS sense lines, insulation monitoring circuits, and auxiliary DC/DC control logic.

Advantages over alternative protection components

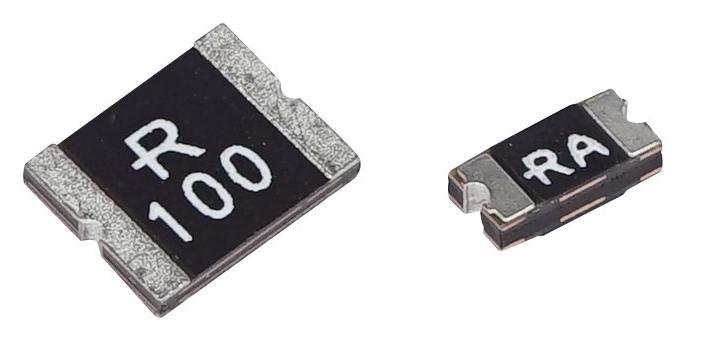

Compared with resettable polymer PTCs and purely electronic current limiting, low-amperage fuses offer highly predictable trip behavior, negligible quiescent power loss, and no long-term drift. Their purely passive structure makes them immune to latch-up and control software anomalies. Designers can fine-tune protection by selecting slow-blow variants for loads featuring brief inrush peaks, or fast-acting versions to defend against even short, sharp surge currents on microcontroller supply rails. Compact surface-mount packages support automated assembly and high-density layouts, while clear visual indication of fuse operation simplifies field diagnostics and speeds service.

Selection, integration, and maintenance considerations

Choosing the right low-amperage fuse requires careful analysis of normal operating current, inrush profile, ambient temperature, and expected fault scenarios. Engineers should review the complete time-current curves rather than only the rated current value, and verify that fuse interruption capacity exceeds potential short-circuit levels in the harness. Placement close to the protected load shortens unprotected conductor length and reduces the risk of collateral heating. In service, documenting fuse ratings and locations in vehicle manuals and digital service tools supports rapid troubleshooting, while periodic inspection in harsh-environment zones helps prevent overlooked failures that may degrade system reliability.

Common questions on low-amperage automotive fuses

1. How do low-amperage fuses protect data and sensor lines?

They isolate small local overcurrent faults before wiring or transceiver ICs are thermally stressed, keeping bus communication stable and preventing cascading failures.

2. What defines the difference between fast-acting and slow-blow types?

Fast-acting versions open quickly under modest overloads, ideal for logic rails, while slow-blow fuses tolerate brief inrush surges from capacitors or electromechanical loads.

3. Why are automotive-grade qualifications important?

Automotive-grade low-amperage fuses undergo extended testing for vibration, temperature extremes, and humidity, ensuring consistent protection performance across the vehicle lifetime.