Marine-Grade Fuse Design Ensuring Corrosion Resistance in Harsh Mobile Environments

News 2025-11-17

Marine-grade fuse corrosion-resistant design suits boats and off-road vehicles by combining robust materials, sealed construction, and stable electrical performance under extreme conditions. In marine and rugged land applications, moisture, salt spray, mud, and continuous vibration accelerate metal degradation and cause intermittent protection failures. A dedicated marine-grade architecture targets these threats at the component level, helping system designers maintain circuit integrity in environments where downtime can be costly or unsafe.

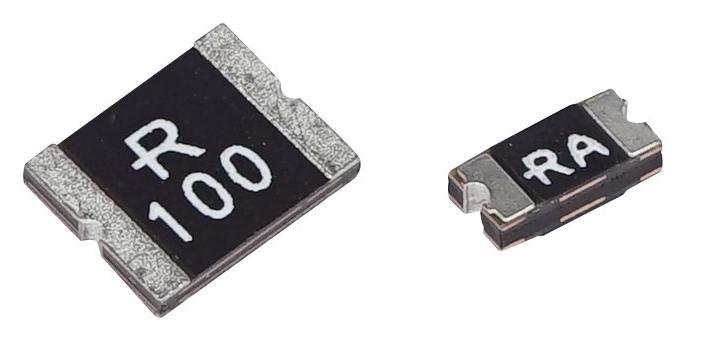

Key Construction Features of Marine-Grade Fuses

Marine-grade fuses use high-purity copper alloy or tinned copper terminations to resist oxidation and galvanic corrosion. Contacts often receive nickel or tin plating, creating an additional barrier against saltwater exposure. Encapsulated fuse elements, high-CTI insulating bodies, and sealed housings limit ingress of moisture and conductive contaminants. Many designs follow IP-rated enclosure concepts, supporting installation in bilge areas, engine compartments, and exposed exterior panels. These construction choices deliver consistent contact resistance, stable time-current characteristics, and longer service life in both marine power distribution and off-road auxiliary circuits.

Performance Advantages in Harsh Electrical Environments

Corrosion-resistant fuse designs maintain low impedance paths even after prolonged exposure to humidity, spray, and temperature cycling. Stable resistance reduces localized heating at terminals, improving accuracy of current-time response under surge and overload conditions. High interrupt ratings support use near batteries, inverters, and high-output alternators that can deliver substantial fault energy. Ruggedized terminations are engineered to handle vibration and shock typical of off-road vehicles, trail rigs, construction machinery, and high-speed watercraft. The result is predictable overcurrent protection that supports safety standards and minimizes nuisance opens caused by deteriorated contacts.

Application Scenarios in Marine and Off-Road Systems

On boats, corrosion-resistant fuses protect navigation electronics, bilge pumps, windlasses, trolling motors, lighting systems, and onboard entertainment equipment. They are typically installed near battery banks and distribution panels to limit fault currents along long cable runs in confined, damp spaces. In off-road vehicles and UTVs, marine-grade fuses are widely adopted to safeguard winches, LED light bars, air compressors, auxiliary power outlets, and aftermarket control modules. Their resistance to splash, mud, and pressure washing suits under-hood and chassis-mounted fuse blocks. RVs, overland trucks, and emergency service vehicles also benefit when circuits must stay operational across wide temperature ranges and corrosive environments such as coastal routes.

Selection and Integration Considerations

Engineers choosing a marine-grade fuse should evaluate continuous current rating, voltage rating, interrupt capacity, and speed characteristics, aligning them with load profiles and inrush conditions. Matching the fuse to marine-grade or sealed fuse holders ensures the corrosion-resistant benefits extend to the entire protection assembly. Proper placement near energy sources minimizes conductor length exposed to faults. Designers should consider standards such as ABYC and ISO marine guidelines, along with OEM requirements for off-road vehicles. Documented salt-spray test results, vibration test data, and thermal cycling performance help confirm long-term durability and support warranty commitments.

1. How does corrosion resistance improve electrical safety?

Corrosion resistance keeps contact resistance low and predictable, preventing hot spots, unstable trip behavior, and unexpected circuit interruptions that could compromise safety systems.

2. Are marine-grade fuses suitable in non-marine vehicles?

Yes, they are widely used in off-road, agricultural, and specialty vehicles where moisture, dirt, and vibration levels exceed typical on-road conditions.

3. Do these fuses require special maintenance procedures?

Routine inspection of fuse blocks and wiring is recommended, but corrosion-resistant construction generally reduces cleaning frequency and replacement caused by environmental damage.