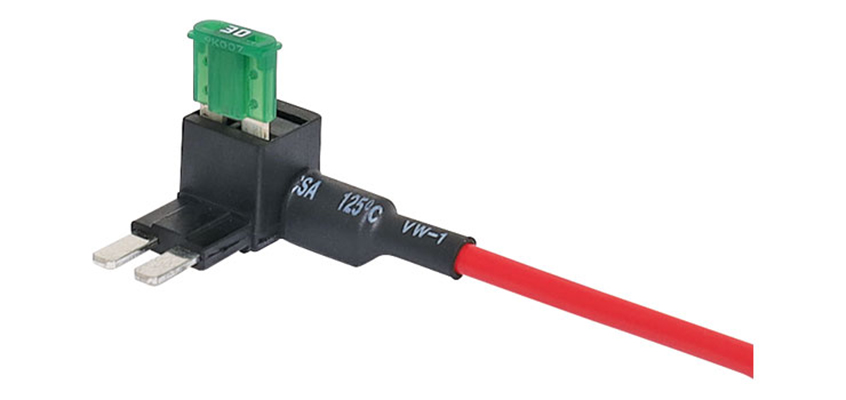

Mini Blade Inline Fuse Holder Ensures Compact Power Protection in Confined Areas

News 2026-01-12

The Mini Blade Inline Fuse Holder offers a compact solution to protect electrical circuits in environments where space is at a premium. Designed to accommodate standard mini blade fuses, this inline enclosure maintains a low profile without compromising durability or safety. Precision-molded with high-quality polycarbonate, it delivers strong resistance to impact and heat for dependable performance in mobile and stationary power systems. Color-coded caps allow quick fuse identification, while integrated wire seals guard against moisture and debris. Its slim form facilitates straightforward inline integration, enabling secure connections on wiring harnesses without added bulk.

Applications and Deployment

Industrial machinery, automotive systems, marine vessels, and solar power setups benefit from the holder’s minimal footprint. In automotive dashboards, its precision-fit casing permits mounting in tight wiring channels, while marine panels leverage corrosion-resistant materials. Solar controllers and battery banks use inline holders to safeguard strings, while RV converters and ATV lighting circuits streamline servicing with reduced clutter.

Performance and Advantages

Supporting fuse ratings from 1A to 30A, the holder covers a broad spectrum of current demands. Its polycarbonate housing insulates up to 600V and complies with UL and RoHS standards. Snap-on caps secure the fuse element while enabling tool-free replacement. Operating between -40°C and 85°C, it withstands extreme conditions, and integrated seals deliver IP65 protection against moisture and dust. Vibration damping ribs reduce mechanical stress, prolonging service life.

Installation and Maintenance Recommendations

Mount the inline fuse holder along harness routes using cable ties or adhesive mounts, avoiding sharp bends that could compromise wire integrity. Strip wires to specification, insert into brass terminals, and crimp with precision tools to guarantee low contact resistance. Conduct routine inspections focusing on cap engagement and terminal condition; the clear housing simplifies visual audits. To swap a blown fuse, twist off the colored cap, replace the element, and snap the cap back—no rewiring required.

Structural Design and Material Selection

Engineered for longevity, the fuse holder body uses UL94 V-0 rated polycarbonate that resists fire and chemical exposure. Brass terminals achieve superior conductivity and corrosion resistance under repeated thermal cycles. A snap-fit base locks securely to panels or harness clips, preventing displacement under vibration. Smooth internal channels guide fuse alignment, reducing installation errors while color-coded cap options enhance part identification during assembly.

Frequently Asked Questions

1、Maximum current rating

Our fuse holder supports mini blade fuses up to 30A, accommodating most low-voltage power circuits.

2、Environmental resilience

Its polycarbonate body and wire seals achieve IP65 protection, resisting moisture, dust, and vibration.

3、Fuse replacement procedure

Rotate and remove the color-coded cap, swap the fuse, and snap the cap back in place—no special tools required.