Mirror heater fuse enhances protection of heated side mirror electrical components

News 2025-11-17

A heated side mirror system faces demanding operating conditions, combining constant exposure to moisture, road debris, and temperature swings. Within this environment, the mirror heater fuse plays a key role in protecting electrical components from overloads, short circuits, and wiring faults. By interrupting abnormal current flow, the fuse shields heater pads, control modules, and harnesses from damage that could lead to unsafe driving conditions, higher maintenance costs, or complete mirror failure.

Application scenarios in modern automotive platforms

Heated side mirror fuses are widely applied in passenger cars, SUVs, commercial trucks, buses, and specialty vehicles used in cold or humid regions. In these scenarios, the heater element must rapidly clear ice, fog, and condensation to maintain rear and side visibility under rain, snow, or freezing conditions. The fuse is installed in the mirror heating circuit, typically integrated into the vehicle’s fuse box or located in a dedicated protection module. It works in coordination with defogger switches, body control units, and mirror adjustment motors, ensuring that any wiring damage, water ingress, or component fault in the mirror assembly does not propagate into the broader vehicle electrical network.

Performance advantages and protection characteristics

The mirror heater fuse delivers precise current limiting tailored to the power profile of the heater pad and associated electronics. Fast response time enables the fuse element to open the circuit in milliseconds under high fault currents, while maintaining sufficient time-delay characteristics to tolerate normal inrush current during heater startup. High breaking capacity prevents arcing and thermal runaway, even under severe short-circuit conditions. Stable temperature derating behavior allows the fuse to maintain predictable protection in low-temperature environments where mirror heaters operate for extended periods. These characteristics reduce the risk of melted connectors, damaged PCB traces, and burned harnesses, improving long-term system reliability.

Design considerations and integration into the electrical system

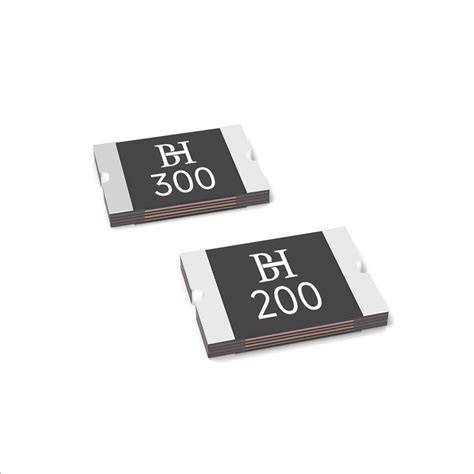

When selecting a mirror heater fuse, engineers must consider heater wattage, nominal system voltage, expected ambient temperature, and peak surge currents. Proper fuse rating ensures that normal heater operation remains unaffected, while maintaining sufficient margin against overloads caused by partial icing or intermittent faults. Compact footprint and standardized blade or mini-blade packages simplify integration into existing automotive fuse blocks. High vibration resistance and corrosion-resistant terminals are required to meet automotive qualification standards and withstand continuous exposure to mechanical shock and moisture. Compliance with ISO, SAE, and OEM-specific requirements supports compatibility across multiple vehicle platforms and simplifies global supply chain management.

Impact on safety, maintenance efficiency, and user experience

By preventing catastrophic failures in the heater circuit, the mirror heater fuse supports safer driving in low-visibility conditions and helps ensure that defogging performance remains consistent throughout the vehicle’s service life. Service technicians can quickly diagnose mirror heating issues by checking the fuse status, significantly shortening troubleshooting time and reducing replacement costs. End users benefit from dependable mirror clearing performance in winter climates, reducing stress during daily commuting and long-distance operations. The combination of targeted protection, simplified maintenance, and extended component lifespan makes the mirror heater fuse a critical part of the overall mirror heating architecture.

1. What causes a mirror heater fuse to blow?

A mirror heater fuse usually opens due to short circuits in the heater pad, damaged wiring, water intrusion inside the mirror housing, or incorrect aftermarket modifications that overload the circuit.

2. How can technicians diagnose a failed mirror heater fuse?

Technicians typically verify the fuse visually or with a multimeter, then check for continuity in the heater element, inspect connectors for corrosion, and confirm that control switches and relays operate within the specified current range.

3. Can upgrading the mirror heater fuse rating improve performance?

Increasing the fuse rating does not enhance heating performance and may expose the circuit to damage. The fuse should always match the manufacturer’s specification to maintain proper protection and electrical safety.