OEM-Quality Fuse Ensures Precise Match To Original Equipment Electrical Performance

News 2025-11-17

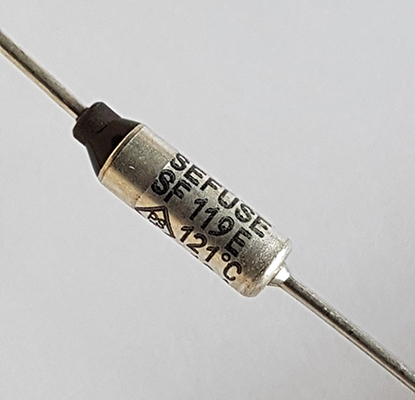

OEM-quality fuses play a decisive role in protecting modern electronic systems, from compact consumer devices to high-power industrial equipment. By matching the exact characteristics of the original equipment fuse, they maintain the designer’s intended behavior under fault, overload, and transient conditions. This precision is not only important for safety and regulatory compliance; it also preserves uptime, prevents damage to expensive components, and supports consistent product performance over the full service life.

Exact Specification Matching And Compliance

OEM-quality fuses are engineered to mirror the original equipment specifications in voltage rating, current rating, time-current curve, breaking capacity, and temperature characteristics. Matching these parameters ensures that the fuse opens at the correct fault level, neither too early nor too late, protecting semiconductors, wiring, and PCB traces as intended. High-quality OEM-grade fuses comply with international standards such as IEC, UL, and RoHS, helping manufacturers and maintenance teams maintain certification status. This level of detail is crucial in sectors like automotive electronics, medical devices, and telecom infrastructure, where regulatory scrutiny and reliability requirements are extremely strict.

Performance Advantages In Demanding Applications

In real-world environments, OEM-quality fuses outperform generic alternatives by offering consistent response under thermal stress, vibration, and electrical noise. In automotive control units, battery management systems, and infotainment modules, correct I²t characteristics and stable resistance values keep circuits protected during cold crank, load dump, or transient spikes. Industrial drives, PLCs, and power supplies depend on precise fuse behavior to safeguard IGBTs, MOSFETs, and control logic, reducing unexpected downtime. The predictable opening characteristics of OEM-matched fuses help prevent nuisance trips, maintain process stability, and extend equipment lifespan.

Key Application Scenarios Across Industries

OEM-quality fuses are widely used in HVAC controllers, smart meters, LED drivers, and data center power distribution units, where dense layouts and elevated ambient temperatures push components close to their limits. In these applications, accurate derating curves and proven endurance under cycling enable designers to run compact, high-efficiency systems without compromising protection. Railway and aerospace electronics demand shock and vibration resistance, while renewable energy inverters and EV charging stations require high DC interrupt ratings and robust arc quenching. Matching the original fuse specifications ensures that field replacements behave exactly as the components validated during design and qualification.

Integration, Selection, And Lifecycle Benefits

Selecting an OEM-quality fuse reduces engineering risk by aligning replacement parts with the original thermal design, PCB footprint, and creepage and clearance requirements. Manufacturers benefit from predictable sourcing, consistent lot-to-lot performance, and full traceability, which simplifies reliability analysis and warranty management. Maintenance teams gain confidence that a replacement fuse will not alter fault-clearing times, EMC performance, or inrush handling, avoiding hidden changes in system behavior. Over the product lifecycle, this accuracy in specification matching helps avoid costly field failures, protects brand reputation, and supports long-term availability of service parts.

Common Questions About OEM-Quality Fuses

1. Why match the exact original fuse specifications?

Using a fuse that duplicates the original voltage, current, and time-current characteristics ensures the circuit responds to faults as designed, maintaining both safety and equipment performance.

2. Where are OEM-quality fuses most commonly used?

They are widely deployed in automotive electronics, industrial automation, medical equipment, power supplies, telecom systems, and renewable energy converters where precise protection is mandatory.

3. Do OEM-quality fuses improve long-term system reliability?

Yes, consistent opening behavior, proven compliance, and stable performance under harsh operating conditions help reduce unplanned outages and extend overall system lifetime.