Optimized Wire Harness Configurations for Automotive Turbocharger Control Electricals

News 2025-10-31

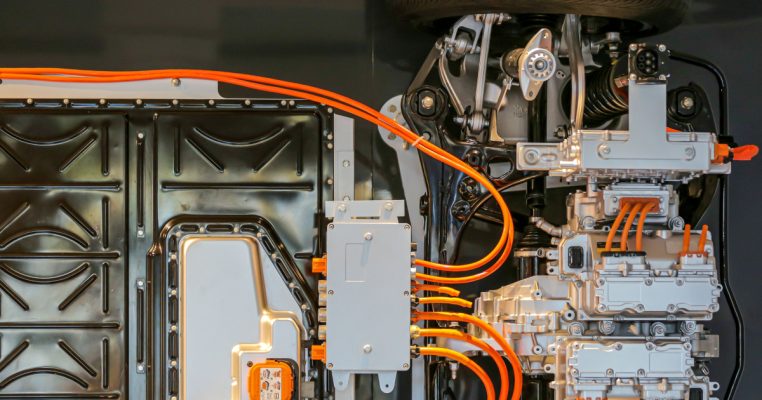

In the realm of automotive engineering, turbocharger systems are pivotal for boosting engine performance and meeting emission regulations. Wire harness configurations form the backbone of the electrical control systems that manage turbocharger operations, including boost pressure and wastegate control. Optimizing these harnesses involves meticulous design to enhance reliability, reduce weight, and improve electrical efficiency. This is particularly important as vehicles become more sophisticated, incorporating elements like variable turbine geometry and electronic actuators. By focusing on optimized configurations, manufacturers can achieve better fuel economy, lower maintenance costs, and increased safety.

Application Scenarios

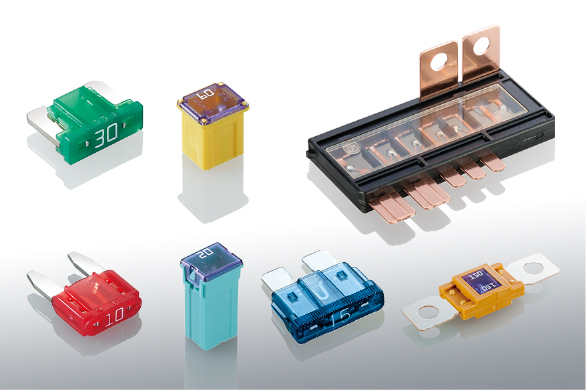

Optimized wire harnesses are deployed in a variety of automotive applications. In high-performance sedans, they ensure precise control for quick acceleration and responsiveness. For utility vehicles, designs account for greater exposure to elements, with enhancements for water and dust resistance. In the context of electric vehicles, these harnesses integrate with high-voltage systems, supporting advanced turbocharger technologies that aid in energy recovery. Additionally, in fleet operations such as buses and trucks, optimized configurations minimize downtime by improving durability against mechanical stresses and thermal cycles.

Performance Advantages

The optimization of wire harness configurations yields several key benefits. Firstly, it reduces the overall weight of the vehicle, contributing to better fuel efficiency and lower CO2 emissions. Secondly, advanced shielding techniques minimize electromagnetic interference, ensuring accurate signal transmission for critical turbocharger functions. Thirdly, the use of high-quality materials enhances resistance to corrosion, abrasion, and high temperatures, leading to longer service life. Furthermore, standardized designs facilitate easier assembly and repairs, reducing manufacturing and operational costs. These advantages collectively support the automotive industry’s shift towards more sustainable and efficient transportation solutions.

Frequently Asked Questions

1. What is the significance of wire harness optimization in turbocharger systems?

It ensures reliable electrical connections that can withstand automotive environments, preventing failures that could affect performance and safety.

2. How do optimized harnesses contribute to cost savings?

Through reduced material usage, fewer components, and easier installation, leading to lower production and maintenance expenses.

3. What future trends are influencing wire harness designs for turbochargers?

Trends include integration with autonomous driving systems and the adoption of lightweight, high-conductivity materials to support electrification.