Panel-Mount Fuse Solutions Enabling Stable Vehicle Circuit Protection In Demanding Environments

News 2025-11-17

Panel-mount fuse secure mounting ensures stable vehicle circuit protection in passenger cars, commercial trucks, off-highway equipment, and specialty EV platforms. By locking the fuse holder directly into the dashboard, control panel, or battery management enclosure, engineers gain consistent contact pressure, improved serviceability, and repeatable performance under harsh operating conditions. This architecture reduces intermittent faults, minimizes downtime, and supports compliance with automotive safety and EMC standards.

Secure Mechanical Design Under Vibration And Shock

Panel-mount fuse holders are engineered to resist vibration, mechanical shock, and thermal expansion common in vehicle cabins, engine compartments, and chassis-mounted panels. Threaded bushings, anti-rotation flats, and snap-in retention tabs prevent loosening over the product lifetime. High-temperature thermoplastic or thermoset bodies maintain structural integrity near power distribution units and under-hood locations. Stable mechanical fixation maintains consistent contact resistance, lowering the risk of localized heating, arcing, or fuse fatigue. These characteristics support long-term reliability in buses, construction machinery, agricultural vehicles, and electric delivery fleets.

Electrical Performance And Protection Capabilities

A well-designed panel-mount fuse interface delivers controlled current paths and predictable fault clearing behavior. Gold or tin-plated terminals reduce contact oxidation, maintaining low impedance under high current loads and repeated fuse replacement cycles. Available ratings typically cover low-voltage 12 V and 24 V systems up to emerging 48 V architectures used in mild hybrids and auxiliary subsystems. Options include fast-acting and time-delay fuses, enabling protection of sensitive ECUs, lighting circuits, infotainment modules, DC-DC converters, and battery heaters. Proper selection of interrupt rating and temperature derating ensures that overcurrent events are cleared safely, protecting harnesses and downstream semiconductors.

Application Scenarios In Modern Vehicle Platforms

Panel-mount fuse solutions are widely used where quick service access, clear labeling, and robust appearance are mandatory. In passenger vehicles, they safeguard seat adjustment motors, sunroof actuators, HVAC blowers, and audio amplifiers through easily accessible console or glove-box panels. In commercial fleets, they protect telematics units, GPS trackers, in-cab inverters, and refrigerated trailer controls, where rapid troubleshooting reduces vehicle idle time. EV charging inlet assemblies, battery pack service panels, and auxiliary power distribution modules also benefit from panel mounting, as maintenance staff can isolate circuits without opening sealed battery enclosures. The format supports clear front-panel markings, helping technicians quickly identify circuit ratings and functions.

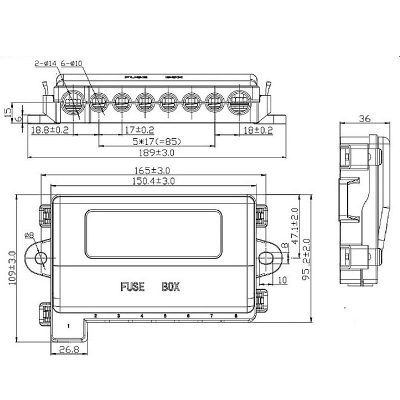

Installation, Safety Standards, And Design Considerations

To achieve stable protection, panel-mount fuse holders must be integrated according to both mechanical and regulatory requirements. Designers choose appropriate panel thickness ranges, torque specifications, gasket materials, and ingress protection ratings such as IP54 or higher for exterior or exposed locations. Compliance with UL, IEC, and automotive-specific standards ensures creepage and clearance distances are maintained in high-humidity or contaminated environments. Using keyed caps and touch-safe designs reduces the risk of accidental contact during fuse replacement. Clear labeling on the panel and documentation in service manuals support quick diagnostics, while using standardized fuse footprints simplifies global sourcing and reduces logistics complexity.

Three Common Questions On Panel-Mount Fuse Use In Vehicles

1Which vehicle circuits benefit most from panel-mount fuse holders?

Circuits that require frequent inspection or field replacement, such as auxiliary lighting, aftermarket electronics, telematics units, HVAC blowers, and low-voltage accessories, benefit strongly from panel mounting due to quick access and minimal downtime.

2How does secure mounting improve long-term circuit stability?

Secure mounting maintains consistent contact pressure under vibration and temperature cycling, which reduces micro-arcing, contact resistance drift, and thermal stress on both the fuse link and wiring, resulting in more predictable overcurrent protection.

3What key factors should engineers verify before specifying a panel-mount fuse holder?

Engineers should confirm current and voltage ratings, interrupt rating, temperature range, panel thickness compatibility, ingress protection requirements, and compliance with relevant automotive and safety standards, along with service accessibility and labeling needs.