Plug-in fuse solutions that simplify automotive circuit protection replacement

News 2025-11-17

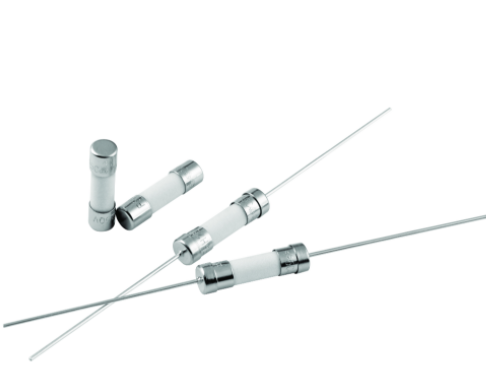

Replacing vehicle fuses in modern automotive electrical systems often demands both speed and precision. Plug-in fuses designed for easy installation help technicians and end users restore power quickly while maintaining strict safety standards. By optimizing geometry, contact plating, and thermal response, these fuses provide dependable circuit protection across passenger cars, commercial fleets, and specialty vehicles where downtime directly impacts productivity and operating cost.

Quick replacement in real-world automotive applications

Plug-in fuse cartridges are widely used in engine control units, body control modules, infotainment systems, and electric power steering circuits. Their standardized footprints allow faulty fuses to be identified and swapped in seconds, often without tools. Fleet maintenance teams benefit from fast troubleshooting during roadside service, since technicians can visually inspect color-coded fuse ratings, pull the defective component, and drop in a new one. In aftermarket upgrades such as high-power audio, auxiliary lighting, and trailer harnesses, plug-in fuses simplify load segmentation and protect wiring looms against short circuits and overload faults.

Performance characteristics and safety advantages

Engineered plug-in fuses offer precise current ratings, stable time–current characteristics, and controlled temperature rise, enabling safe protection of sensitive ECUs and wiring harnesses. High-conductivity alloy contacts minimize contact resistance, reducing heat generation at the fuse holder interface. Many automotive plug-in fuses comply with ISO and SAE standards, ensure high interrupting capacity, and maintain performance over wide ambient temperatures typical in engine bays and under-dash locations. The clear melt indicator inside the housing allows quick fault confirmation without test equipment, lowering diagnostic time and avoiding unnecessary part replacement.

Design flexibility and integration into fuse boxes

Automotive designers favor plug-in fuses because they integrate cleanly into compact fuse boxes and power distribution centers. Uniform blade dimensions support high-density layouts, enabling dozens of protected circuits in a small footprint. Optional low-profile variants help meet dashboard and center-console packaging constraints. The plug-in architecture also supports modular expansion: additional accessory circuits can be added by routing new lines to spare fuse positions, simplifying late design changes. In electric and hybrid vehicles, segmented DC bus structures often rely on plug-in fuses to isolate battery, charger, and auxiliary loads, allowing service teams to remove power safely during maintenance.

Maintenance efficiency and cost benefits over time

Compared with soldered or hardwired protection, plug-in fuses significantly reduce service time and training requirements. workshop staff can quickly teach drivers how to replace basic fuses using the vehicle manual, reducing unnecessary service visits. The low unit cost of standardized automotive plug-in fuses enables economical stocking of full rating ranges, from low-current signal lines to higher-current auxiliary loads. Inventory management becomes easier because the same fuse families can be deployed across multiple vehicle platforms and model years, supporting long-term availability and consistent protection performance.

Common questions about plug-in automotive fuses

1. How do I select the correct plug-in fuse rating?

Choose a current rating that matches the circuit’s specified fuse value on the fuse box diagram, ensuring both voltage rating and time–current characteristics meet the vehicle manufacturer’s requirements.

2. Can plug-in fuses be used in high-temperature engine compartments?

Yes, many automotive plug-in fuses are rated for extended temperature ranges and are qualified for use in engine bays, but it is important to use components that meet the specified automotive standards.

3. What are signs that a plug-in fuse needs replacement?

Loss of function in the protected circuit, a visibly melted fuse element, or discoloration of the fuse body indicates that the device has opened and must be replaced using the same type and rating.