Quick-Acting Thermal Fuse Protects Modern Vehicle Electronics From Excessive Heat Damage

News 2025-11-27

Quick-acting thermal fuses are becoming key safety elements in modern vehicles, where densely packed electronic control units operate in harsh thermal environments. As electric and hybrid platforms add higher power levels, battery management systems, on-board chargers, infotainment units, and ADAS modules all face rising heat stress. An accurately calibrated thermal fuse interrupts current when a preset temperature is exceeded, preventing meltdown of wiring, connectors, or semiconductor devices and helping automakers meet stringent functional safety and reliability standards.

Key Operating Principle and Construction

A quick-acting thermal fuse consists of a temperature-sensitive pellet or alloy, a spring mechanism, and contact terminals enclosed in a compact, insulated housing. Under normal operating conditions, the fusible element maintains firm contact so current flows freely with minimal resistance. When the local temperature surpasses the rated threshold, the element changes state, releasing the spring and opening the circuit permanently. This one-time action delivers predictable cutoff behavior independent of software, sensors, or power cycling, making thermal fuses a robust last line of defense in automotive electronic assemblies.

Performance Advantages in Vehicle Electronics

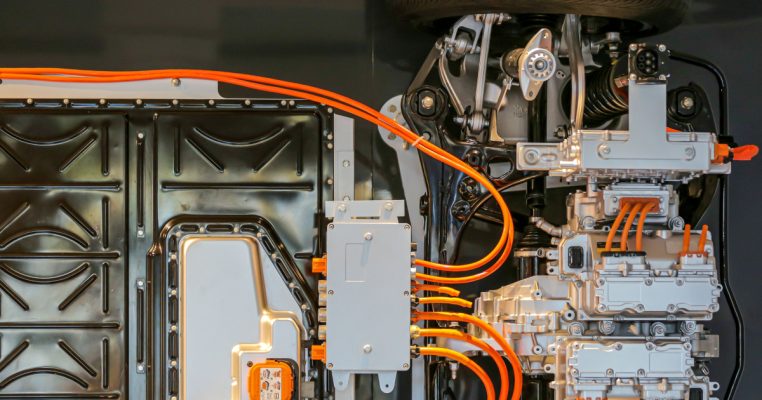

Compared with conventional overcurrent fuses or resettable PTC devices, quick-acting thermal fuses respond directly to temperature rather than current alone. This characteristic allows targeted protection of heat-sensitive modules such as DC/DC converters, LED driver boards, and lithium-ion cell packs exposed to local hot spots. Tight trip tolerances, fast response near the rated threshold, and low leakage current support stable system behavior. Compact form factors and low series resistance help designers preserve board space and efficiency, while AEC-Q compliant variants match the vibration, humidity, and wide temperature ranges encountered in under-hood and chassis applications.

Typical Automotive Application Scenarios

Automotive engineers integrate thermal fuses into wiring harnesses, battery modules, blower motors, seat heaters, and power distribution boxes to curb heat-related damage and fire risk. In traction battery packs, a thermal fuse can isolate a cell group if abnormal heating occurs during charging or regenerative braking, preventing propagation to adjacent cells. In comfort systems such as steering wheel or seat heaters, the fuse disconnects power when mechanical faults or blocked airflow elevate temperatures beyond design limits. LED headlamps, infotainment units, and camera modules also benefit from localized thermal fusing that protects delicate PCBs inside compact housings exposed to sunlight and engine heat.

Selection, Integration, and Design Considerations

Selecting the right thermal fuse requires careful alignment of opening temperature, rated current, and environmental endurance to the target application. Engineers must consider worst-case ambient conditions, thermal coupling to heat sources, and expected fault scenarios when choosing the fuse rating and mounting position. Good thermal contact to the protected component, appropriate lead length, and adherence to derating curves ensure accurate response. Validation testing under temperature cycling, surge conditions, and mechanical shock helps confirm that the fuse operates within specification across the vehicle lifetime while coordinating properly with upstream fuses and electronic protection circuits.

Application FAQs

1How does a thermal fuse differ from a standard automotive fuse?

A thermal fuse responds to excessive temperature instead of only overcurrent. It opens the circuit when a preset temperature is reached, protecting modules from overheating even when current remains within nominal limits.

2Where should designers place thermal fuses in EV battery systems?

They are typically positioned close to cell groups, busbars, or PCB hotspots where abnormal heating could initiate thermal runaway. Proper placement ensures rapid sensing of local temperature rise.

3Can a quick-acting thermal fuse be reset after operation?

No, it is a one-shot protective device. Once it opens due to overheating, it must be replaced to restore circuit continuity.