Safety-Certified Design Thermal Fuse Ensures Stable Overtemperature Protection in Power Systems

News 2025-11-27

Thermal fuses play a decisive role in safeguarding modern electronics, particularly where compact layouts and high power density intensify thermal stress. A safety-certified-design thermal fuse engineered to comply with major international protection standards, including IEC, UL, and VDE, offers predictable cutoff behavior when abnormal temperatures occur. By interrupting the circuit once its calibrated melting point is reached, it prevents overheating, fire hazards, and damage to sensitive components. This type of device is now a standard element in chargers, home appliances, LED drivers, industrial controllers, and battery-powered equipment.

Compliance and Safety Standards

Compliance with international protection standards is the core value of a safety-certified thermal fuse. Devices are tested for rated current, interrupting capacity, insulation resistance, dielectric strength, and long-term stability under elevated temperature and humidity. Certification files reference specific operating temperatures and fault scenarios so design engineers can match a particular fuse rating to their worst-case conditions. Standardized performance data improves documentation for product safety approvals and simplifies global market entry, supporting OEMs that supply equipment to multiple regions.

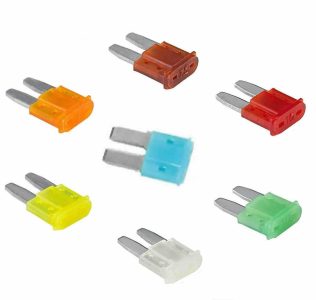

Key Performance Characteristics and Construction

The performance of a modern thermal fuse depends on its internal construction. A calibrated alloy pellet or organic material responds to a defined temperature threshold, separating spring-loaded contacts and permanently opening the circuit. Typical offerings cover operating currents from a few hundred milliamps up to tens of amperes, with cut-off temperatures ranging from approximately 72 °C to 240 °C. Low internal resistance minimizes self-heating and power loss, while compact axial or radial packages ease placement near hotspots such as transformer windings, MOSFETs, or rectifier bridges. Robust lead wires support automated soldering and ensure low contact resistance over the product lifetime.

Application Scenarios in Consumer and Industrial Systems

In consumer electronics, thermal fuses are widely embedded in switching power adapters, hair dryers, coffee machines, vacuum cleaners, and microwave ovens to block runaway temperature rise due to blocked airflow, stalled motors, or control circuit failure. In LED lighting, they protect driver modules and constant-current supplies against thermal overload caused by poor heat dissipation. Industrial applications include motor windings, transformer assemblies, UPS systems, energy storage units, and power distribution panels where high ambient temperatures and continuous operation demand rigorous safety margins. In these systems, the fuse is often paired with temperature sensors and control ICs to build layered protection.

Design Considerations and Integration Benefits

When selecting a thermal fuse, engineers must consider rated voltage, current, cutoff temperature, maximum ambient temperature, and expected fault profile. The device should be placed in direct thermal contact with the main heat source using secure clamping, insulating sleeves, or thermally conductive adhesives, while maintaining creepage and clearance distances required by safety standards. Integrating a certified thermal fuse reduces dependence on complex firmware protection alone and helps manufacturers achieve higher safety classifications in product datasheets. It also stabilizes field performance by providing a predictable, non-resettable fail-safe that maintains user safety even if control firmware or sensors malfunction.

1, How does a thermal fuse differ from a temperature switch?

A thermal fuse opens the circuit once and remains permanently open, while a temperature switch is resettable and cycles on and off around its set point.

2, Where should the fuse be placed in a power supply?

It should be mounted close to the main heat source, often near transformers, switching devices, or high-loss resistors, where the highest fault temperatures are expected.

3, Why is certification important for global deployment?

Certification according to IEC, UL, and related standards demonstrates verified safety performance, enabling faster approvals from regulatory bodies and access to international markets.