Sealed Fuse Box for Marine Vehicles Corrosion-Resistant Electrical Safety

News 2025-10-31

In the challenging marine environment, electrical systems face constant threats from saltwater, humidity, and mechanical stress, making reliable protection essential. A sealed fuse box designed for corrosion resistance addresses these issues by providing a durable enclosure that shields fuses and circuits from degradation. This ensures uninterrupted operation and enhances safety in marine vehicles such as boats, ships, and offshore platforms. By preventing water ingress and corrosion, these fuse boxes maintain electrical integrity, reducing the risk of failures that could lead to costly downtime or hazards.

Applications in Marine Environments

Sealed fuse boxes are vital in various marine settings where exposure to harsh conditions is unavoidable. On commercial fishing vessels, they safeguard systems for navigation, communication, and engine controls against salt spray and moisture. In recreational boating, they protect essential components like bilge pumps, lighting, and audio systems, ensuring functionality during long trips. For larger applications such as cargo ships or military crafts, these fuse boxes offer robust defense in high-risk areas, complying with standards from organizations like the International Maritime Organization (IMO). Their design also suits offshore oil rigs, where reliable electrical performance is critical for safety and efficiency.

Key Performance Advantages

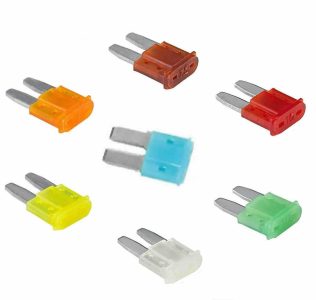

The sealed fuse box excels through its advanced materials and engineering, offering superior durability in corrosive marine conditions. Constructed from corrosion-resistant alloys or specialized polymers, it withstands salt, chemicals, and UV exposure without compromising integrity. Tight sealing mechanisms, including gaskets and clips, prevent moisture entry, while integrated ventilation manages heat to avoid overheating in confined spaces. This results in extended component lifespan, lower maintenance costs, and enhanced reliability. Additionally, user-friendly features like clear labeling and easy access for fuse changes improve operational efficiency, making it a smart choice for marine electrical upgrades.

Frequently Asked Questions

1. What materials are used for corrosion resistance in these fuse boxes?

Answer: Typically, stainless steel, anodized aluminum, or high-grade polymers are used, as they resist rust and chemical degradation in marine environments.

2. How does sealing improve electrical safety on marine vehicles?

Answer: Sealing blocks water and contaminants, reducing short circuit risks and preventing electrical fires, which is crucial for safe operations at sea.

3. Can these fuse boxes be installed in existing marine systems?

Answer: Yes, they are designed for compatibility with standard marine wiring and fuse types, allowing for easy retrofitting without major modifications.