Space-Efficient Thermal Fuse Enhancing Safety in High-Density Vehicle Power Networks

News 2025-11-27

In modern vehicles, electrical architectures grow denser as more comfort, safety, and infotainment systems are integrated into compact spaces. Harnesses run close to power distribution units, battery junction boxes, and DC/DC converters, often leaving little room for conventional protection devices. A space-efficient thermal fuse addresses this limitation by combining compact dimensions, precise trip characteristics, and high interrupt capability, enabling safer and more efficient packaging in crowded compartments such as under-dash modules and engine bays.

Compact Design Tailored to Vehicle Packaging Constraints

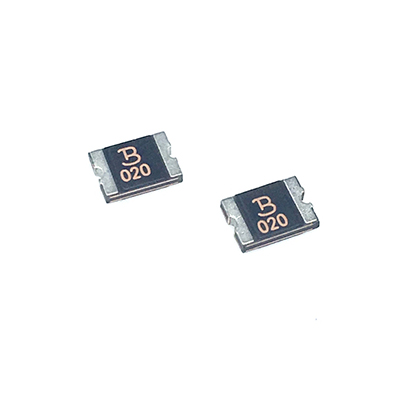

A key advantage of a space-efficient thermal fuse is the minimized footprint and low profile, allowing placement directly on densely populated PCBs or within slim fuse blocks. Reduced body size supports shorter conductor paths, cutting resistive losses and improving overall system efficiency. Optimized lead geometry and robust terminations simplify automated assembly, while tight dimensional tolerances ensure repeatable fit within standardized automotive housings. This makes the device highly suitable for body control modules, seat control units, and battery management controllers where every millimeter counts.

Thermal Performance and Protection Accuracy

The fuse integrates a calibrated thermal element that responds accurately to overcurrent-induced temperature rise, disconnecting the circuit before insulation damage or connector deformation occurs. Stable opening temperatures and well-defined time–current curves reduce nuisance tripping during inrush events such as motor start-up or capacitive charging. High breaking capacity allows the fuse to handle fault conditions present in 12 V, 24 V, and emerging 48 V architectures. Low contact resistance and carefully selected materials maintain low self-heating, ensuring consistent performance across a wide ambient temperature range typical of engine compartments.

Automotive Application Scenarios and Integration Benefits

Application areas include electric power steering, HVAC blowers, seat heaters, window lifters, ADAS sensor power rails, on-board chargers, and auxiliary battery loops. In these systems, the thermal fuse acts as a last line of defense against sustained overload, wiring harness shorts, or mechanical blockage in motors. Its compact form factor enables strategic placement closer to potential failure points, improving fault discrimination and reducing the risk of cascading damage. Designers can integrate the fuse into modular power distribution centers, achieving higher circuit density without compromising serviceability or diagnostic transparency.

Reliability, Standards Compliance, and OEM Value

The device is engineered to meet stringent automotive quality expectations, including AEC-Q compliant testing, vibration and shock robustness, and long-term thermal cycling endurance. Stable behavior over lifetime supports predictive maintenance strategies and enhances OEM confidence in high-current zones. Clear marking, documentation, and traceable part numbering aid in service and field replacement. By combining compact dimensions, accurate thermal response, and high interrupt ratings, the space-efficient thermal fuse helps manufacturers reduce wiring mass, improve safety margins, and optimize packaging in next-generation vehicles.

1. Where is a space-efficient thermal fuse typically used in vehicles?

It is frequently deployed in body control modules, power distribution units, battery junction boxes, and motor-driven loads such as pumps and blowers.

2. How does the thermal fuse improve protection accuracy?

The calibrated thermal element and defined time–current curve ensure opening occurs at predictable temperatures, limiting damage from sustained overloads while minimizing nuisance trips.

3. Is this thermal fuse suitable for 48 V architectures?

Yes, the high interrupt rating and low resistance design support use in 12 V, 24 V, and 48 V systems when selected according to the specified voltage and current limits.