Strategies for Glass Fuse Replacement in Truck Electrical Systems

News 2025-10-27

Glass fuses play a critical role in protecting truck electrical systems from overloads and short circuits. In the demanding environment of commercial trucks, these components safeguard vital wiring and devices, preventing potential fires or breakdowns. Common applications include lighting systems, engine controls, and accessory circuits where reliability is essential. Their transparency allows for easy visual inspection, making them ideal for quick diagnostics during roadside checks. This article explores effective replacement methods to ensure optimal performance and longevity in truck operations.

Glass fuses offer superior performance in truck environments due to their fast response times and precise current ratings. They handle vibrations and temperature fluctuations better than some alternatives, enhancing system durability on long hauls. Key scenarios include heavy-duty trucks facing extreme weather, where these fuses maintain circuit integrity without degrading. Their compact design fits into tight spaces, providing an edge in modern vehicle layouts for better space efficiency and reduced weight.

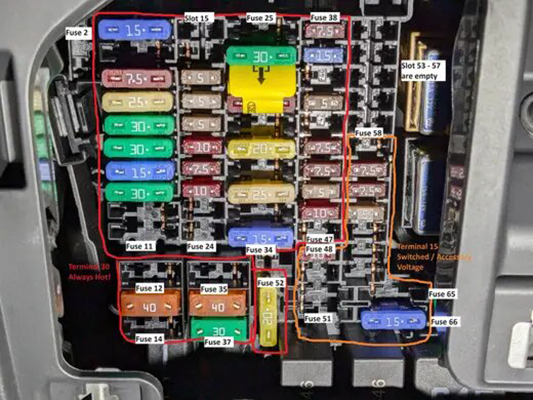

Replacing a glass fuse begins with identifying the faulty unit through multimeter testing or visual checks for discoloration. In trucks, access points are often under the dashboard or in fuse boxes near the battery, requiring basic tools like pliers and a fuse puller. Ensure the vehicle is powered off to avoid shocks, then remove the old fuse and insert a matching replacement. This method minimizes downtime, allowing drivers to resume routes quickly while maintaining electrical safety standards.

Regular inspection of glass fuses can prevent failures in truck electrical systems, focusing on corrosion or loose connections that affect performance. Drivers should check fuses during routine maintenance schedules, especially after off-road trips or exposure to moisture. By selecting fuses with appropriate amperage for specific applications, such as high-draw winches or lights, operators extend component life and improve overall vehicle efficiency. This proactive approach reduces repair costs and enhances reliability on the road.

1. What tools are needed for fuse replacement?

A basic set including pliers and a multimeter.

2. How often should fuses be inspected in trucks?

At least every six months or after major trips.

3. Can glass fuses be reused?

No, they should be replaced once blown to ensure safety.