Strategies for Improving Corrosion Resistance in Auto Fuses for Vehicles in Coastal and Snowy Regions

News 2025-10-24

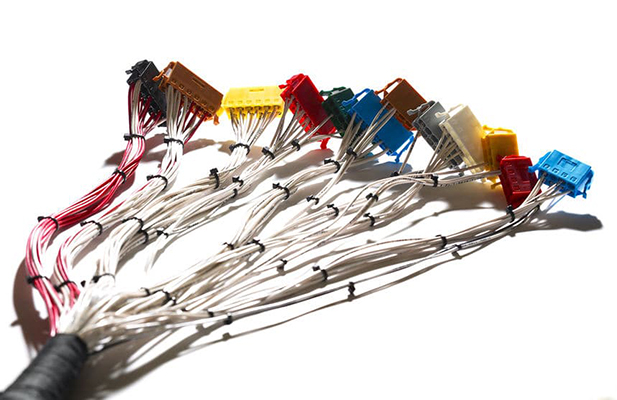

Auto fuses are critical components in vehicle electrical systems, safeguarding circuits from overloads and short circuits. In harsh environments like coastal and snowy regions, corrosion poses a significant threat, potentially leading to failures that compromise safety and reliability. This article explores how enhanced corrosion resistance in auto fuses addresses these challenges, focusing on material innovations and design improvements that ensure longevity and performance under adverse conditions.

Challenges Posed by Coastal Environments

Coastal areas expose vehicles to salt-laden air and high humidity, which accelerate corrosion on metal parts. Auto fuses, often made from copper or other conductive materials, can degrade rapidly, leading to increased resistance or complete failure. By incorporating corrosion-resistant coatings and alloys, such as those with zinc or nickel plating, fuse manufacturers can extend service life and maintain electrical integrity. This is particularly vital for vehicles in marine proximity, where salt spray can penetrate seals and cause pitting or oxidation, underscoring the need for robust materials that withstand these corrosive elements.

Difficulties in Snowy and Cold Climates

In snowy regions, vehicles face freeze-thaw cycles and moisture accumulation that promote rust and electrochemical corrosion. Auto fuses must endure temperature fluctuations that can cause condensation and accelerate degradation. Advanced fuse designs with sealed housings and corrosion-inhibiting materials help mitigate these issues, ensuring consistent performance during winter conditions. For instance, fuses engineered with composite materials resist moisture ingress, reducing the risk of short circuits in icy environments and enhancing overall vehicle dependability in areas with heavy snowfall and road salting.

Frequently Asked Questions

1. What causes corrosion in auto fuses located in coastal areas?

Answer: Salt spray and humidity create an electrolytic environment that breaks down protective layers on fuse metals, leading to accelerated rust and degradation.

2. How does corrosion resistance benefit vehicles in snowy conditions?

Answer: It prevents moisture-induced failures, ensuring fuses operate reliably in cold temperatures and reducing the likelihood of electrical malfunctions during harsh weather.

3. What key materials enhance auto fuse corrosion resistance?

Answer: Materials like stainless steel alloys, specialized coatings, and polymer seals are used to shield fuses from environmental factors, improving durability and longevity.