Thermal Fuse Introduction and the Manner of Working

News 2026-01-12

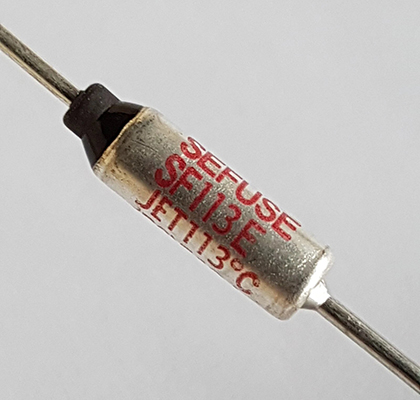

Temperature fuse, also known as thermal fuse (GB9816.1-2013), is a temperature-sensing circuit-breaking device. It can sense overheating caused by abnormal operation of electrical and electronic products and cut off the circuit to prevent fires. It is commonly used in hair dryers, irons, rice cookers, electric stoves, transformers, motors, water dispensers, coffee pots, etc. Once a temperature fuse operates, it cannot be reused and only acts once at the melting temperature.

The following matters must be observed to ensure the normal operation of the temperature fuse:

i) Each temperature fuse has a rated current and voltage, a melting temperature (Tf), a service temperature (Th), and a maximum temperature (Tm). It must be used within the specified parameters.

ii) When selecting the installation position of the fuse, it is necessary to ensure that the vibration inside the finished product and the displacement of other components do not transfer stress to the fuse.

iii) It should be installed in a place where the temperature will not rise above the maximum service temperature after the fuse melts.

iv) It should not be used in machines with liquids or humidity maintained at over 95%.

v) The temperature fuse should be installed in a place where it can only sense the heat source of the temperature fuse. When it is unavoidable in the structure, a thermal barrier should be set up, for example, when installed on a heater, it should not be directly connected to avoid the heating wire heating the temperature fuse.

vi) Parallel connection to increase the current capacity of the temperature fuse or continuous passage of overcurrent and overvoltage will damage the internal contacts of the temperature fuse and affect its normal operation. Therefore, it cannot be used under the above conditions.

Although the temperature fuse is designed with high reliability, the abnormal situations that a single temperature fuse can handle are still limited. In addition, if the temperature fuse is damaged due to human factors or unforeseeable force majeure and cannot function normally, the circuit cannot be cut off in time when the machine malfunctions. Therefore, in cases where the machine overheats, the incorrect operation directly affects human safety, there is no circuit breaker other than the fuse, or in situations requiring high safety, two or more temperature fuses with different melting temperatures should be used.

The thin type temperature fuse is specially developed for over-temperature protection of lithium-ion batteries. Its working principle is the same as the second type of temperature fuse mentioned above. It uses a low-melting-point alloy to connect the circuit, and the low-melting-point alloy is surrounded by a flux resin. The low-melting-point alloy is connected to the metal contact and sealed with plastic material. When a short circuit or other reasons cause the internal temperature of the battery to rise to a certain level, the temperature fuse attached to the battery cell will quickly melt, thereby cutting off the external circuit of the battery and preventing battery explosion and personal injury. As handheld electronic devices become increasingly portable, the size of the temperature fuse needs to be as small and thin as possible. Currently, the thinnest temperature fuse can be as thin as 0.65mm and as wide as 2.7mm. The internal resistance of the temperature fuse is also very small, only about 8mΩ, and the standby power consumption is very small, which can greatly increase the standby time of the lithium-ion battery.

It also has certain disadvantages. First, it is non-recoverable, unlike PTC. Even if an accidental fault causes the PTC to act, once the fault is eliminated, the battery can continue to work. Once the temperature fuse acts, the entire battery cannot work anymore. Of course, as the quality of lithium-ion batteries improves, the probability of such accidental faults becomes smaller and smaller. Once an abnormality occurs, the battery cannot be used anymore, which has instead become an advantage of the temperature fuse. After all, the cost of a battery is negligible compared to a personal injury incident. As the saying goes, it is better to err on the side of caution than to let something go. Once a mobile phone battery has experienced a high-temperature fault, who would dare to carry this potential bomb around? Second, it cannot be welded and processed in the ordinary way, such as PPTC, which can withstand short-term high temperatures, so it can be welded through a reflow soldering furnace and directly injected into the battery. However, the temperature fuse can only be welded locally by spot welding or laser welding to prevent it from melting. Currently, the thin type temperature fuses with melting points of 98℃ and 92℃ are widely used. Under a heating rate of 1℃/min, the melting temperature of the 98℃ thin type temperature fuse is 94±3, and that of the 92℃ thin type temperature fuse is 89+3/-4, which is 85℃ to 92℃. At present, some domestic manufacturers are developing thin type temperature fuses with higher melting points. Temperature fuses can be classified as: