Uniform Conductivity Auto Fuse Enhancing Consistent Vehicle Circuit Performance And Safety

News 2025-12-08

Uniform conductivity auto fuses play a decisive role in stabilizing modern vehicle electrical architectures. As wiring harnesses grow denser and loads become more dynamic, predictable fuse behavior turns into a core requirement for safety, diagnostic accuracy, and long‑term reliability. By maintaining consistent conductive properties across the fuse element, these components reduce variability in current carrying capacity, opening the door to precise coordination with sensors, ECUs, and smart power distribution modules.

Design Principles And Electrical Characteristics

Uniform conductivity in an auto fuse starts with carefully selected alloys and controlled manufacturing of the fuse link. The cross‑section, resistivity, and thermal characteristics are matched so the element heats uniformly under load, providing tight tolerance on current ratings and melting times. This predictable I²t behavior supports targeted protection of lighting circuits, HVAC blowers, infotainment units, and powertrain subsystems. Low contact resistance at the terminals limits local hotspots, while stable impedance over the service life reduces measurement error in current sensing strategies.

Key Performance Advantages In Automotive Platforms

The main advantage of a uniform conductivity auto fuse lies in the consistent trip profile across wide temperature ranges and duty cycles. Vehicles operate in harsh environments, so a fuse that maintains its characteristics in cold‑start conditions and high‑temperature engine bays helps avoid nuisance blows and hidden overstress. Stable conductivity supports accurate load profiling, enabling OEMs to calibrate circuit breakers and solid‑state relays around the fuse. The result is improved uptime, reduced service callbacks, and more predictable protection of sensitive ECUs, sensors, and communication buses such as CAN and LIN.

Application Scenarios Across Vehicle Subsystems

Uniform conductivity auto fuses find broad application in traditional 12 V architectures and emerging 48 V subsystems. In body control modules they protect central locking, window lifters, seat adjusters, and comfort features where frequent actuation demands consistent inrush handling. In powertrain and chassis domains these fuses safeguard fuel pumps, ignition coils, ABS modules, and electric steering units that require strict current discrimination to protect both wiring and semiconductor drivers. Electric vehicles and hybrids benefit as well: battery junction boxes, DC‑DC converters, and on‑board chargers can rely on predictable fuse behavior during fault events, supporting safe isolation strategies and compliance with automotive safety integrity levels.

Integration, Standards Compliance And Selection Considerations

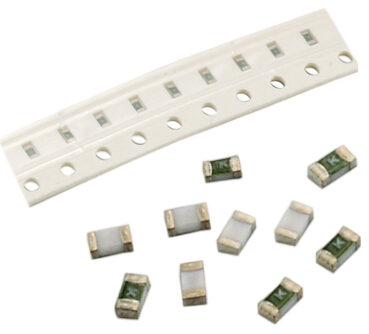

When specifying a uniform conductivity auto fuse, engineers evaluate rated current, voltage, breaking capacity, and time‑current characteristics against regional and automotive standards such as ISO, SAE, and OEM‑specific requirements. Mechanical form factor, including blade style, mini or micro dimensions, and color coding, must align with fuse holders and service expectations in the field. Low variation batch‑to‑batch enhances quality control and simplifies global sourcing. By pairing these fuses with accurate current sensors and smart junction boxes, designers can implement diagnostic features such as blown‑fuse detection, load optimization, and predictive maintenance, strengthening overall vehicle safety and reducing warranty costs.

1. Typical automotive applications

Uniform conductivity auto fuses are widely used in body electronics, powertrain control, chassis systems, infotainment, and energy storage protection, particularly wherever stable current ratings and repeatable tripping are critical.

2. Benefits compared to conventional blade fuses

They offer tighter tolerance on current ratings, more predictable I²t performance, reduced nuisance tripping, and better coordination with advanced semiconductor drivers and electronic control units.

3. Key factors when selecting a fuse

Engineers should review nominal and peak load profiles, ambient temperature, wiring gauge, required fault clearing time, mechanical compatibility, and compliance with applicable automotive safety and performance standards.