Waterproof Fuse Sealed Construction Resists Moisture in Harsh Vehicle Environments

News 2025-11-17

In modern automotive electrical systems, fuse integrity directly affects safety, uptime, and service life. Vehicles operating in off‑road, marine, agricultural, or winter highway conditions are constantly exposed to water spray, road salt, mud, and condensation. Traditional open or semi‑sealed fuse holders allow moisture and contaminants to penetrate, creating corrosion paths and potential short circuits. Waterproof fuses using sealed construction address these risks by enclosing the fuse element in a robust, moisture‑tight housing engineered specifically for harsh vehicle environments.

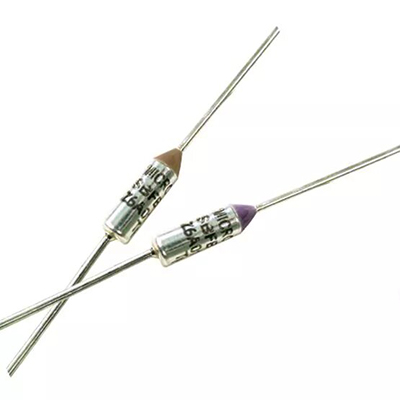

Sealed Construction and Design Features

Waterproof fuse designs typically combine a sealed plastic or thermoset body, precision‑molded gaskets, and overmolded terminals to block moisture ingress. High‑grade elastomer seals maintain compression over a wide temperature range, preventing gaps during thermal cycling. The internal fuse link is isolated from ambient humidity, while plated terminals and corrosion‑resistant alloys limit oxidation. Many sealed automotive fuses are tested to IP67 or IP69K, ensuring resistance to high‑pressure wash‑down, immersion, and dust. These design elements not only protect the fuse element but also stabilize contact resistance, which is essential for accurate current protection in high‑load circuits.

Key Performance Advantages in Vehicle Electronics

The primary performance advantage of a waterproof sealed fuse is long‑term stability under aggressive environmental stress. By preventing moisture and conductive debris from reaching the fuse and contacts, these components reduce nuisance blowing caused by corrosion‑driven heating and leakage currents. Consistent contact quality supports precise time‑current characteristics, allowing engineers to coordinate fuse ratings with alternators, batteries, and sensitive ECUs. The sealed housing also minimizes the risk of arcing and tracking along contaminated surfaces, improving system safety in 12 V, 24 V, and emerging 48 V architectures. In fleet and heavy‑duty transport, this translates into fewer electrical failures, reduced maintenance intervals, and lower total cost of ownership.

Typical Application Scenarios in Harsh Environments

Sealed waterproof fuses are widely deployed in exterior and chassis‑mounted circuits that see direct exposure to road and weather conditions. Common applications include engine bay power distribution, ABS and traction control modules, lighting harnesses, trailer connectors, and auxiliary power systems for snowplows, winches, and liftgates. Off‑highway equipment such as tractors, construction machinery, mining trucks, and forestry vehicles rely on sealed fuses to protect hydraulic pump controls, telematics units, and lighting bars in muddy, high‑spray environments. Marine and recreational vehicles also benefit, where saltwater, vibration, and temperature swings can rapidly corrode unsealed fuse connections.

Integration, Standards, and Selection Considerations

When integrating waterproof fuses into a vehicle platform, engineers evaluate mounting style, footprint compatibility, and service accessibility. Many sealed fuse families are available in standard blade formats so they can be used in sealed power distribution boxes without redesigning the entire harness. Compliance with automotive standards such as ISO, SAE, and OEM‑specific environmental test protocols is crucial for qualification. Designers must consider voltage rating, interrupting capacity, temperature derating, and expected surge conditions from motor loads or inductive circuits. Careful selection of fuse rating, combined with sealed construction, ensures that protection devices remain stable over the vehicle lifetime, even under constant vibration, shock, dust, and moisture.

1, What makes a waterproof fuse different in harsh vehicle environments?

A waterproof fuse uses sealed construction, gaskets, and corrosion‑resistant materials to block moisture and contaminants, maintaining stable protection performance in wet and dirty conditions.

2, Where are sealed waterproof fuses most commonly used in vehicles?

They are typically used in engine compartments, under‑chassis power distribution, exterior lighting systems, trailer connections, off‑road equipment, and marine or recreational vehicles exposed to water and spray.

3, How does a sealed fuse improve maintenance and uptime?

By preventing corrosion and moisture‑induced failures, sealed fuses reduce unexpected circuit interruptions, extend service intervals, and help fleets keep vehicles in operation longer.